How to Measure Inch Pounds without a Torque Wrench: Easy and Effective Methods

Do you need to measure inch pounds but don’t have a torque wrench? This common dilemma can be frustrating, especially if you’re dealing with delicate calibration or precision work. However, there are ways to measure inch pounds without a torque wrench. The key is to understand the concept of torque and leverage and to have the right tools on hand.

In this article, we’ll explore some simple methods you can use to measure inch pounds accurately and reliably, even without a torque wrench. Whether you’re a DIY enthusiast or a professional mechanic, these tips and tricks will come in handy for all your torque-related needs. So, let’s get started!

Understanding Inch Pounds

If you’ve ever tried measuring inch pounds but don’t have a torque wrench, you might be wondering how to do it accurately. Inch pounds are a unit of measurement used to indicate torque, which is the amount of force needed to tighten a bolt or nut. To measure inch pounds without a torque wrench, you’ll need a good quality torque screwdriver.

This tool comes with a calibrated scale indicating the amount of torque being applied, measured in inch pounds. It’s important to note that torque screwdrivers can measure a specific range of inch pounds, so be sure to choose one that fits the application you’re working on. With a torque screwdriver, you can easily tighten bolts and nuts to the required torque specification without risking over- or under-tightening.

So, if you don’t have a torque wrench but need to measure inch pounds, consider investing in a torque screwdriver to get the job done accurately.

Explanation of Inch Pounds

If you’re unfamiliar with inch pounds, it can be confusing to understand what they are and how they’re used. Inch pounds are a measurement of torque, which is the amount of force required to rotate an object around an axis. Unlike foot pounds, which measure the force applied to an object with a lever arm one foot long, inch pounds measure torque with a lever arm one inch long.

To put it simply, inch pounds are a unit of measurement used to determine the amount of force needed to tighten or loosen bolts and screws in a variety of applications. This measurement is important in industries such as automotive, construction, and engineering, where precise torque specifications are necessary for safety and functionality. So, if you ever come across the term “inch pounds” in your work or hobbies, you now have a better understanding of what it means and why it matters.

Why Inch Pounds are Important in Certain Applications

Inch Pounds When it comes to certain applications, inch pounds play a critical role in ensuring precision and accuracy. Inch pounds are a unit of measurement used to quantify torque, which is the twisting force applied to an object. This measurement is especially important in applications where a specific level of tightness is required to avoid damage or ensure proper function.

For example, working on delicate electronic equipment or assembling machinery with tight tolerances requires an understanding of inch pounds. Measuring and applying torque using inch pounds helps ensure that the force applied is consistent and within the necessary range. Overall, understanding inch pounds can be crucial in maintaining the quality and durability of products and equipment.

Alternative Methods for Measuring Inch Pounds

When it comes to measuring inch pounds, a torque wrench is undoubtedly the most accurate and reliable tool to use. However, if you don’t have access to one, there are alternative methods that can be used. A common method is to use a beam-type torque wrench, which operates by visual inspection of a marked scale as the torque is applied.

Another option is to use a digital torque adapter, which can be attached to a standard ratchet or breaker bar to give you a digital readout of the applied torque. Keep in mind that these alternative methods may not be as accurate as using a torque wrench, so it’s important to calibrate your tool before each use and take multiple readings to ensure consistency. Nonetheless, with a little bit of patience and a steady hand, you can measure inch pounds without a torque wrench.

Using a Beam Style Torque Wrench

When it comes to measuring inch pounds, there are alternative methods to using a beam style torque wrench. One such method is using a digital torque adapter that can be attached to a regular wrench handle. This device can convert your regular wrench into a digital torque wrench, allowing you to accurately measure inch pounds.

Another option is a dial torque wrench, which uses a dial gauge to display the torque measurement. Both of these alternatives are useful in situations where a beam style torque wrench may not be available or practical to use. It’s important to remember, however, that accuracy is key when measuring torque, so it’s important to choose a method that is reliable and consistent for your specific application.

Using a Cheater Bar and a Socket Wrench

When it comes to measuring inch pounds, there are plenty of options available to you. While using a torque wrench is one possibility, you can also make use of a cheater bar and socket wrench. A cheater bar is essentially an extension that attaches to your socket wrench, providing you with additional leverage.

This extra force can help you torque your bolts to the desired level without having to exert as much physical effort. However, it’s important to note that using a cheater bar can be dangerous if you’re not careful. You’ll need to make sure you’ve properly secured your bolts and that you’re not putting too much force on them.

Additionally, you can’t always get an accurate measurement with this method, as you may not be applying exactly the same amount of force each time. Despite this, using a cheater bar and socket wrench can be a useful alternative when you don’t have a torque wrench available.

Using a Spring Scale

If you don’t have a torque wrench, you might be wondering how to measure inch pounds. A great alternative method is using a spring scale. First, attach the spring scale to the end of the bolt you want to measure.

With the scale attached, apply force to the scale until the bolt starts to turn. The amount of force you applied is the torque in inch pounds. However, it’s important to note that this method only provides approximate measurements.

If precision is crucial, a torque wrench is a better option. But if you’re in a pinch and need to measure inch pounds, a spring scale is a cost-effective solution.

Tips and Best Practices for Accurate Measurement

If you don’t have a torque wrench on hand but still need to measure inch pounds accurately, there are several tips and best practices you can follow. First, ensure that the tool you are using to apply the force is consistent, such as a calibrated screwdriver or torque screwdriver. Next, use a reliable reference point for measuring the amount of force applied, such as a digital scale or a reference chart based on the size and material of the object being tightened.

It’s also important to take consistent readings and repeat the process several times to ensure accuracy. In addition, be sure to factor in any external variables that may affect the measurement, such as temperature or humidity. By following these tips and best practices, you can measure inch pounds without a torque wrench with confidence and accuracy.

Choosing the Right Auxiliary Tool

When it comes to accurate measurement, choosing the right auxiliary tool is crucial. One important tip is to ensure that the tool you use is suitable for the type of measurement you need to take. For example, a ruler or tape measure is great for length measurements, but may not be the best option for volume or weight measurements.

Additionally, it’s important to use a tool with clear and precise markings to avoid inaccuracies. When measuring liquids, be sure to use a graduated cylinder or other similar tool which can easily show the volume. Lastly, it’s important to always calibrate your auxiliary tool before using it to ensure that it is accurate.

By following these tips, you can use the right auxiliary tool to obtain accurate measurements every time.

Understanding the Physics Behind Torque

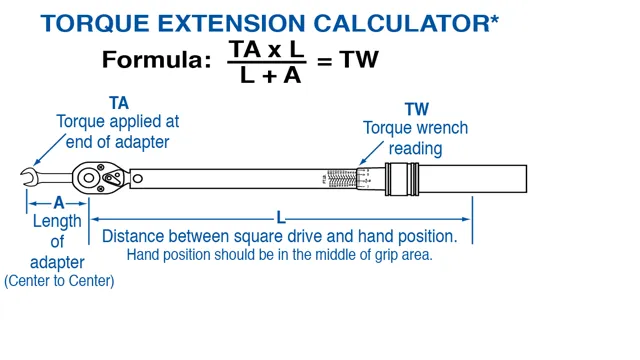

Torque measurement is an essential part of any mechanical system, as it helps determine the rotational force applied to an object. However, accurate measurement of torque can be a challenging task, especially when dealing with high levels of precision. To ensure accurate measurements, it is important to follow certain tips and best practices that can minimize errors.

One such tip is to use proper equipment, such as calibrated torque wrenches, that can provide precise readings. Additionally, ensuring that the equipment is properly maintained and stored can prevent damage or wear that may affect the accuracy of measurements. Another critical factor is proper technique, which involves ensuring that the torque is applied at a consistent and precise angle, and avoiding any undue influence on the torque reading.

Finally, taking multiple readings and averaging them can help reduce the effects of any outliers or noise in the measurements and provide more accurate data. Understanding these key practices can help ensure that torque measurement is both accurate and reliable, allowing for more efficient and effective use of mechanical systems.

Keeping the System Stable during Measurement

When it comes to taking measurements, maintaining stability in the system is crucial for obtaining accurate results. There are a few tips and best practices to keep in mind to ensure your measurements are as precise as possible. First of all, make sure to eliminate any external sources of vibrations or interference in the measurement environment.

This can include turning off nearby equipment or controlling for temperature changes. Additionally, be sure to use the appropriate tools and equipment for the type of measurement being taken. This can include using shielding to protect against electromagnetic interference or using a high-quality sensor to capture the data.

Finally, take multiple measurements at different intervals to account for any variations and identify any potential outliers. By following these best practices, you can ensure stable and accurate measurements every time.

Conclusion

Inch pounds may seem like an obscure and daunting measurement, but fear not! With a few simple household items and a little know-how, you too can accurately measure inch pounds without a torque wrench. Whether using a fish scale, a ruler and a weight, or even just your own two hands, measuring inch pounds has never been easier or more accessible. So go forth, measure with confidence, and impress your friends with your newfound knowledge of torque.

After all, as the wise old saying goes, “If you can’t measure it, you can’t improve it.”

FAQs

What is the formula for converting foot pounds to inch pounds?

To convert foot pounds to inch pounds, multiply the number of foot pounds by 12.

Can I measure inch pounds with a regular wrench?

Yes, you can use a beam-type torque wrench or a click-type torque wrench to measure inch pounds.

How do I measure inch pounds with a beam-type torque wrench?

With a beam-type torque wrench, you need to look at the scale and line up the pointer with the desired reading.

What is the difference between inch pounds and foot pounds?

Inch pounds measure torque in smaller units than foot pounds. 1 foot pound is equal to 12 inch pounds.

Can I use a digital caliper to measure inch pounds?

No, a digital caliper cannot measure torque. You need a specialized torque wrench to measure inch pounds.

How accurate are digital torque wrenches for measuring inch pounds?

Digital torque wrenches are highly accurate and can measure torque up to +/- 2% of the set value.

How do I check if my torque wrench is calibrated correctly for measuring inch pounds?

You can check the calibration of your torque wrench with a calibration tool or by sending it to a professional calibration service.