Can I Use a Drill Press for Milling? Everything You Need to Know

If you’re looking to expand your metalworking capabilities, you might be wondering if you can use a drill press to do milling. Well, the answer is yes! With a few modifications and some know-how, you can turn your drill press into a makeshift milling machine. But before you get started, there are a few things you need to know.

While a drill press can handle basic milling tasks, it’s not designed for heavy-duty milling or precision work. Additionally, milling with a drill press requires specific bits, cutting tools, and clamping systems. However, with the right approach, using a drill press for milling can be a convenient and cost-effective way to tackle small milling projects.

In this article, we’ll cover everything you need to know about milling with a drill press, including the necessary equipment, techniques, and safety tips. So grab your safety glasses and let’s get started!

Understanding the Differences Between a Drill Press and a Milling Machine

Can I use a drill press for milling? While a drill press and a milling machine may seem similar, they serve different purposes. A drill press is primarily used for drilling holes, whereas a milling machine is designed to cut material using a rotating cutter. The main difference between the two lies in the movement of the material.

A drill press moves the material up and down, whereas a milling machine moves it side to side, up and down, and back and forth. This extra movement provides more control and precision, allowing for more complex shapes to be cut. While it is possible to use a drill press for light milling operations, it is not recommended for more complex machining tasks.

It is essential always to use the correct tool for the job to achieve accurate and safe results, considering the safety concerns. By using a milling machine instead of a drill press, you can avoid unnecessary risks and achieve precise, high-quality results.

Drill Press vs Milling Machine: Features and Capabilities

If you are in the market for a new machining tool, it’s important to understand the differences between a drill press and a milling machine. While both can be instrumental in metalworking and woodworking, their features and capabilities are quite distinct. A drill press is primarily used for drilling holes in materials and is typically less expensive than a milling machine.

Meanwhile, a milling machine can not only drill but also cut and shape metal and wood, making it a more versatile and robust tool. Think of a drill press as a hammer and a milling machine as a Swiss Army knife. While both can be useful in their own right, a Swiss Army knife provides more options and capabilities.

Ultimately, when choosing between a drill press and a milling machine, consider your specific needs and desired results to determine which tool is best suited for your project.

Advantages and Disadvantages of Using a Drill Press for Milling

When it comes to working with metal and other materials, it’s important to understand the differences between a drill press and a milling machine. While a drill press can be used for some milling tasks, it’s not ideal for all of them. A drill press is great for drilling holes, but it lacks the precision and power of a milling machine for more complex milling tasks.

Additionally, a milling machine allows for more versatility with the types of cuts you can make and the types of materials you can work with. However, there are still advantages to using a drill press for milling. For one, a drill press is more affordable than a milling machine, making it accessible to hobbyists and smaller operators.

Additionally, a drill press can be easier to use for those new to milling, and it takes up less space in a workshop. Overall, it’s important to choose the right tool for the job. If you’re working on more complex milling tasks or need greater precision and power, a milling machine is likely the best choice.

But for simpler tasks and those just starting out with milling, a drill press can still be a useful tool. It’s important to weigh the advantages and disadvantages of each and choose the tool that best fits your needs.

Preparing Your Drill Press for Milling

Can I use a drill press for milling? Yes, you absolutely can! However, there are a few steps that you need to take in order to prepare your drill press for milling projects. Firstly, you need to make sure that you have the right collet or chuck for the milling bits that you plan on using. Most drill presses come with a chuck that can hold drill bits that have a cylindrical shank, whereas milling bits typically have a flat shank that needs to be held in a collet or specialized chuck.

Secondly, you need to make sure that your drill press is properly secured on a stable surface, as milling will apply lateral force that could cause the machine to tip over if it’s not properly anchored. Additionally, you need to ensure that your workpiece is securely clamped down in order to prevent the lateral forces from moving it around during milling. Finally, you need to adjust the speed of your drill press to match the type of material and milling bit that you’re using, as the wrong speed can cause the bit to break or reduce the quality of the milling.

By properly preparing your drill press for milling, you can achieve precise and accurate milling on your chosen materials.

Choosing the Right Drill Bits and End Mills

When preparing your drill press for milling, it’s essential to choose the right drill bits and end mills. The drill bits are used to make holes in the material, while end mills are used to cut and shape the material. The first step is to check the chuck on your drill press.

Ensure that it can accommodate the shank diameter of the end mill you plan to use. Next, inspect the spindle and work table to make sure they are clean and free of debris. You don’t want any dust or chips to interfere with the accuracy of your milling.

Lastly, adjust the speed of the drill press. The speed should be set to suit the diameter and material you are working on. Too fast, and you risk damaging the bit or burning the material.

Too slow, and the bit can become excessively hot, causing it to dull quickly. By following these steps and selecting the proper tools, you can prepare your drill press for milling with confidence.

Setting Up Your Workpiece and Clamping It Securely

When preparing your drill press for milling, one of the most important steps is setting up your workpiece and clamping it securely. This ensures that the workpiece remains in place while you perform the milling operation, preventing any errors or accidents. To begin, you’ll need to choose the right drill bit for the material you’ll be working with, as well as the appropriate milling cutter or end mill.

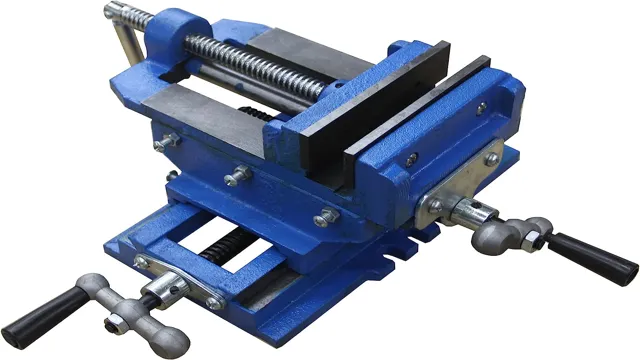

You’ll also need to adjust the height of the drill press table to match the height of the cutter, and make sure that the workpiece is centered under the spindle. Once you’ve positioned the workpiece correctly, use clamps or a vise to hold it securely in place. This will prevent the workpiece from moving during the milling process, which can result in inaccurate or uneven cuts.

By taking the time to properly set up your workpiece and clamp it securely, you can ensure that your milling operation is successful and produces the desired results.

Making Adjustments to Your Drill Press for Milling

When it comes to turning your drill press into a milling machine, proper preparation is crucial to achieve quality results. Without taking the necessary steps to adjust your drill press, you risk damaging your equipment and potentially causing injury. One of the critical elements of preparing your drill press for milling is to align the drill chuck and milling bit to ensure they are perfectly centered.

You can do this by using a centering tool or a piece of thick paper to check alignment and make adjustments as needed. Additionally, make sure to adjust the drill press speed and depth stop to accommodate the milling operation’s requirements. By taking the time to properly prepare your drill press, you can get the most out of your milling tasks and achieve accurate and precise cuts.

Milling Techniques for a Drill Press

Many DIY enthusiasts wonder if a drill press can be used for milling, and the answer is yes! With proper techniques and accessories, a drill press can be turned into a mini milling machine. One important factor to consider is the type of bit to use. A high-speed steel end mill or a carbide end mill can be used for milling, and it’s important to choose the right size based on the material and depth of the cut.

In addition, clamping the material securely to the table and using a fence can ensure accuracy and prevent the material from moving during milling. Another important consideration is the speed and feed rate. It’s essential to follow manufacturer guidelines and not push the drill press beyond its capabilities.

With the right techniques and accessories, a drill press can be a versatile tool for milling small projects.

Basic Milling Operations You Can Do with a Drill Press

Drill Press Milling Techniques A drill press can be surprisingly versatile when it comes to milling workpieces. Although traditional milling machines are designed for the job, a drill press can function as a makeshift milling machine if you use the right techniques. The basic milling operations you can perform on a drill press include drilling, reaming, countersinking, and counterboring.

These operations can be done both manually or via attachments that transform the drill press into a milling machine. The key to using a drill press for milling is to take things slow and steady and ensure that the workpiece is tightly secured in place. Using the right tools and maintaining a consistent, manageable pace can help produce precise cuts.

With some practice, a drill press can be a viable option for milling small parts at home or in a workshop.

Advanced Milling Techniques and Tips for Better Results

When it comes to milling on a drill press, there are some techniques you can use to achieve better results. Firstly, it’s important to adjust the speed of your drill press to match the type of material you’re milling. For example, if you’re milling hardwood, you’ll want to use a slower speed setting.

On the other hand, if you’re milling softwood, you can use a faster speed setting. Additionally, you’ll want to use a milling bit that’s appropriate for the size and type of material you’re working with. A larger bit is ideal for milling thicker material, while a smaller bit is more appropriate for finer detail work.

Another important thing to keep in mind when milling on a drill press is to use a consistent and steady pressure when feeding the material through the cutter. By doing so, you can achieve a smooth and clean finish without causing any damage to your workpiece. Overall, with the right technique and attention to detail, milling on a drill press can be a great way to achieve precise and professional results for your projects.

Safety Considerations When Milling with a Drill Press

If you’re wondering whether it’s safe to use a drill press for milling, there are a few things you should consider before diving in. First and foremost, you’ll want to make sure your drill press is sturdy and well-secured, as milling can put a lot of force on the equipment. Additionally, you should invest in a milling vise or clamping kit to help hold your materials in place.

It’s also a good idea to wear eye protection and use a coolant to help prevent overheating and reduce the risk of injury. While a drill press can be a useful tool for milling, it’s important to take the necessary safety precautions to ensure a successful and injury-free experience. Ultimately, the decision to use a drill press for milling will depend on your individual skills and the specific project at hand, but with the right tools and precautions, it can be a handy option.

Conclusion

In the never-ending quest to push the limits of our tools, the question of using a drill press for milling inevitably arises. While it may seem like a convenient shortcut, the truth is that a drill press simply wasn’t designed for the demands of milling. Attempting to use one for such a purpose is like trying to turn a butter knife into a Samurai sword – sure, it technically might work, but it won’t be pretty.

So, unless you enjoy frustration and disappointment (and potential injury), I’d recommend sticking to the proper tool for the job. Happy milling!”

FAQs

What is the difference between a drill press and a milling machine?

A drill press is primarily used for drilling and tapping operations, whereas a milling machine is used for cutting and shaping various materials.

Can a drill press be used for milling?

Yes, a drill press can be converted into a milling machine with appropriate attachments and modifications.

What are the advantages of using a milling machine over a drill press?

A milling machine can perform a wider range of operations, including cutting, drilling, shaping, and threading with greater precision and accuracy.

Can I use a drill press for metal milling?

Yes, a drill press can be used for milling metals with appropriate cutting tools and techniques.

What safety precautions should be taken when using a drill press for milling?

Safety glasses, work gloves, and hearing protection should be worn, and the workpiece should be securely clamped to prevent movement during milling operations.

What are the primary limitations of using a drill press for milling?

The limited range of movements and adjustments compared to a dedicated milling machine can limit the accuracy and precision of milling operations.

Can a drill press be used for milling wood or other soft materials?

Yes, a drill press can be used for milling a variety of materials, but the cutting tools and techniques may vary depending on the material’s characteristics.