Can You Put a Wire Wheel on a Bench Grinder? A Comprehensive Guide to Bench Grinder Attachments.

If you’re looking for a versatile tool that can help you clean, polish, and sharpen metal objects, a wire wheel attached to a bench grinder is an excellent choice. By putting a wire wheel on a grinder, you can create an efficient machine that can handle a wide range of tasks. However, the process of installing a wire wheel on a bench grinder can be intimidating if you’re new to the world of power tools.

Don’t worry; we’ve got you covered. This blog post will guide you through the steps to put a wire wheel on a bench grinder so that you can start working on your metalworking projects right away. So, let’s get started!

Understanding Wire Wheels

When it comes to wire wheels, it’s important to understand the limitations of your equipment. While a bench grinder may seem like the perfect tool for sharpening and polishing your wire wheels, it’s important to note that not all bench grinders are created equal. Some models may not have the necessary power or speed to handle the demands of a wire wheel.

Additionally, using a wire wheel on a bench grinder can be dangerous if not done properly. It’s important to use the correct safety precautions and techniques to avoid injury. That being said, if you have the appropriate bench grinder and take the necessary safety measures, you can use a wire wheel to achieve great results on your metalworking projects.

So, can you put a wire wheel on a bench grinder? The answer is yes, but it’s important to take the necessary precautions and use the appropriate equipment.

What are wire wheels?

Wire wheels are a type of wheel commonly found on vintage and classic cars. They are composed of thin metal spokes that extend from the hub to the outer rim of the wheel. These spokes are often twisted or bent to create intricate patterns and designs, giving wire wheels a unique and elegant appearance.

Wire wheels were first introduced in the early 20th century and gained popularity in the 1920s and 1930s. Today, they are still used on some newer cars as a symbol of luxury and prestige. While they may look delicate, wire wheels are actually quite strong and durable, able to withstand the weight and pressure of a car driving on rough roads.

Types of wire wheels

Wire wheels come in various types, each with unique features that cater to different needs. One of the most common types is the standard wire wheel, which consists of evenly-spaced spokes attached to a hub. These types of wheels are perfect for light-duty applications and provide a good balance between strength and weight.

Another type of wire wheel is the twisted wire wheel, which has twisted or spiral-shaped spokes. This design makes the wheel stronger and better-suited for heavy-duty tasks. A third type is the knotted wire wheel, which has wire strands that are twisted and knotted together.

This type of wheel is ideal for removing rust, paint, and other surface coatings from metal. Finally, the crimped wire wheel has wire strands that are crimped together, providing a more aggressive cutting action. No matter the type, wire wheels are a versatile tool that is essential for any metalworking project.

Benefits of wire wheels

Wire wheels have been a popular choice for car enthusiasts for years, and for good reason. Not only do they add a touch of vintage charm to any vehicle, but they also offer a host of benefits. Understanding wire wheels can help you make an informed decision about whether they are right for your car.

One of the primary benefits of wire wheels is their lightweight construction. This can improve your car’s handling and performance, making for a smoother ride. Additionally, wire wheels are built to flex, which can help absorb shock and reduce vibrations on the road.

They also offer superior heat dissipation, which can keep your brakes cooler and help prevent brake fade. Whether you’re restoring a classic car or simply looking to upgrade your ride, wire wheels are a great choice. They offer a unique blend of style, performance, and durability that is hard to beat.

So if you’re looking for a way to take your car to the next level, consider investing in a set of high-quality wire wheels.

Selecting the Right Wire Wheel

Yes, you can put a wire wheel on a bench grinder, but it is important to select the right kind of wire wheel for your specific needs. Wire wheels come in different sizes, wire thickness, and materials such as steel, brass, and nylon. They also come with different textures and bristle densities, which can be coarse or fine depending on the type of surface you want to polish or clean.

Choosing the right combination of wire wheel and bench grinder can make a big difference in the quality and speed of your work. If you need to remove rust, paint, and other stubborn debris from tough materials such as metal, steel wire wheels with coarse bristles are your best bet. However, if you need to clean delicate surfaces such as porcelain, brass or wood, you might prefer a soft-bristled nylon or brass wire wheel.

It is recommended to always wear safety glasses when using a wire wheel on a bench grinder, as the high-speed rotation of the wheel can cause flying debris.

Matching wire wheel to bench grinder

When it comes to matching a wire wheel to your bench grinder, there are a few things you need to consider. First and foremost, you need to choose the right wire wheel for the job. There are a variety of different types and styles of wire wheels available, each with their own unique properties and benefits.

Some of the most common wire wheel types include crimped wire wheels, knotted wire wheels, and twisted wire wheels. Crimped wire wheels are ideal for lighter-duty applications, such as removing rust and paint from metal surfaces. They feature softer wire bristles that are less likely to scratch or damage delicate surfaces.

Knotted wire wheels, on the other hand, are designed for heavy-duty applications. They feature tightly twisted wire bristles that can be used for removing scale, rust, and other stubborn materials. Twisted wire wheels are somewhere in the middle, offering a balance between crimped and knotted wire wheels.

When choosing a wire wheel, it’s important to consider the type of material you’ll be working on, as well as the level of aggression that’s required. You’ll also need to choose a wire wheel that’s designed to fit your specific bench grinder. Most bench grinders use either 6-inch or 8-inch wire wheels, so make sure you choose the right size.

Additionally, check the maximum RPM rating of your bench grinder and select a wire wheel that’s rated for the same or higher speed. By taking these factors into consideration, you should be able to select the right wire wheel for your bench grinder and the job at hand. Remember to always use the proper safety gear when working with wire wheels, including eye protection, gloves, and a dust mask.

With the right wire wheel and proper safety precautions, you’ll be able to tackle even the toughest metalworking projects with ease.

Choosing wire wheel type and size

When it comes to choosing the right wire wheel, the first thing to consider is the type of work you will be doing. For lighter jobs such as cleaning and removing rust, a crimped wire wheel is ideal. On the other hand, for heavier-duty tasks like weld blending and surface preparation, a knotted wire wheel is more suitable.

Once you have decided on the type of wire wheel, the next thing to consider is the size. A larger wheel means a wider surface area that can be worked on at one time. However, a smaller wheel offers more precision and can reach tighter spaces.

It’s always best to choose a wheel size that matches the size of the area you will be working on. Remember, selecting the right wire wheel for the job helps ensure a smoother and more efficient work environment.

Considerations for safety

When selecting a wire wheel, safety should be a top consideration. Choosing the right wire wheel can help prevent accidents that may cause serious injury or damage to property. One important factor to keep in mind is the type of wire used in the wheel.

Different wire types are designed for different applications, such as cleaning rust or removing paint, so it’s crucial to select the appropriate wire for your intended use. Another factor to consider is the speed of the tool, which should be compatible with the wire wheel to avoid overheating or breakage. Additionally, it’s important to ensure that the wire wheel is securely mounted and balanced to avoid any potential vibrations or wobbling that can cause accidents.

By taking these precautions, you can use a wire wheel confidently and safely for all your projects.

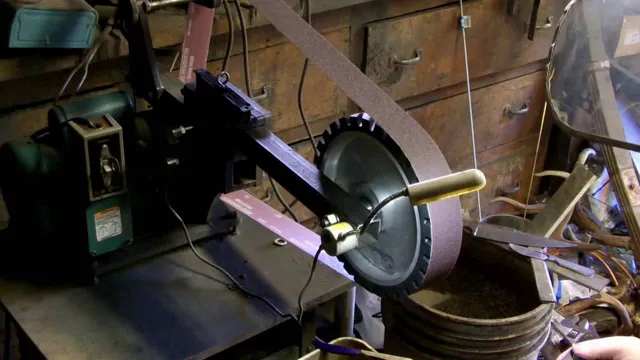

Installation of the Wire Wheel on the Bench Grinder

Yes, you can put a wire wheel on a bench grinder, but it’s important to make sure you use the correct installation process. To install a wire wheel on your bench grinder, start by removing any attachments or wheels already in place. Next, check the size of your bench grinder’s arbor to ensure it matches the size of your wire wheel.

If not, there are bushings available to adapt the arbor size. Once you’ve checked the arbor size, slip the wire wheel onto the arbor and thread on the washer and retaining nut. Tighten the nut with a wrench, being sure to follow the manufacturer’s torque recommendations.

You can then attach the safety guard and plug in your grinder before testing your new wire wheel. Remember to make sure your wire wheel is rated for the RPMs of your bench grinder to avoid any accidents.

Step by step installation guide

If you’re looking to add a wire wheel to your bench grinder, don’t worry – it’s easier than you might think. The first step is to gather your supplies. In addition to the bench grinder and wire wheel, you’ll need a wrench, safety glasses, and gloves.

Next, make sure your grinder is unplugged and secure. Use the wrench to remove the current grinder wheel, being careful not to damage the shaft or threads. Then, attach the wire wheel by screwing it onto the shaft and tightening it with the wrench.

Once it’s secured, put on your safety gear and plug in the grinder. Turn it on and gently touch the wire wheel to a scrap piece of metal to ensure it’s spinning evenly and won’t cause any damage. And voila! You’ve successfully installed a wire wheel on your bench grinder.

Now you’re ready to tackle all kinds of rusty, grimy surfaces.

Tips for proper installation

When it comes to installing a wire wheel on a bench grinder, there are a few important things to keep in mind. First, make sure you select a wire wheel that is the appropriate size for your grinder. You should also take the time to inspect the wheel and make sure there are no cracks or other damage before attempting to install it.

Once you’re ready to install the wheel, start by disconnecting the power to the grinder. Then, loosen the wheel nut and slide the wire wheel onto the spindle. Tighten the nut by hand as much as possible, and then use the wrench that came with your grinder to tighten it the rest of the way.

Be sure not to overtighten the nut, as this can cause the wheel to warp or crack over time. With these tips in mind, you’ll be able to install a wire wheel on your bench grinder safely and effectively.

Conclusion

In conclusion, putting a wire wheel on a bench grinder is like giving a racecar a turbo boost. It takes a tool that’s already efficient at grinding and sharpening and elevates it to a whole new level of versatility and power. So, if you’re looking to up your workshop game and tackle a wider range of tasks, don’t hesitate to give this upgrade a spin!”

FAQs

What is a wire wheel attachment?

A wire wheel attachment is a tool used for cleaning and polishing surfaces.

Can a wire wheel be attached to a bench grinder?

Yes, a wire wheel can be attached to a bench grinder as long as it is compatible with the grinder’s specifications.

What are the advantages of using a wire wheel on a bench grinder?

Using a wire wheel attachment on a bench grinder can help in removing rust, paint, and other coatings from surfaces. It can also help in buffing and polishing metal surfaces.

Can wire wheels be used for sharpening tools on a bench grinder?

No, wire wheels are not suitable for sharpening tools on a bench grinder. Instead, use a grinding wheel designed specifically for sharpening tools.

What safety precautions should I take when using a wire wheel attachment on a bench grinder?

Always wear proper protective gear, including eye protection and gloves. Ensure that the wire wheel is securely mounted and not damaged. Keep your hands and fingers away from the wire wheel while it is in use.

How can I maintain a wire wheel attachment on a bench grinder?

Clean the wire wheel frequently to remove any debris or buildup. Check for any signs of wear or damage and replace the wire wheel if necessary. Store the wire wheel in a dry and clean place when not in use.

Can a wire wheel attachment be used on other power tools besides a bench grinder?

Yes, wire wheel attachments can be used on other power tools such as drills, angle grinders, and rotary tools. However, make sure that the attachment is compatible with the tool and that you follow the manufacturer’s instructions.