Do You Always Clamp on a Drill Press? Learn Why It’s Important for Safe and Accurate Drilling

Are you struggling with the decision of whether or not to clamp your workpiece when using a drill press? Well, you’re not alone. This is a common question that many woodworkers, metalworkers, and DIY enthusiasts find themselves asking. On one hand, clamping your workpiece can provide stability and prevent it from slipping or spinning during the drilling process.

On the other hand, it can also damage your workpiece or create unwanted marks. So, what’s the answer? To clamp or not to clamp? It’s a tricky question that depends on various factors such as the size of your workpiece, the type of material, and your personal preference. In this blog, we’ll explore the pros and cons of clamping when using a drill press and help you make an informed decision.

Think of it like driving a car. Sometimes you need to put your hands at 10 and 2 on the steering wheel to have maximum control, while other times you only need one hand on the wheel to steer with ease. Similarly, sometimes clamping is essential for precision, while other times it can hinder your progress.

It’s all about finding the balance that works for you. So, buckle up and let’s dive deeper into the clamping vs. not clamping debate.

Whether you’re a beginner or a seasoned pro, there’s always something new to learn about drill press techniques. Let’s get started!

Introduction

Do you always clamp on a drill press? Well, the answer is, it depends. Clamping your material on a drill press is usually necessary for safety reasons. It ensures that your material won’t slip or get caught in the bit, causing harm to you or damaging your material.

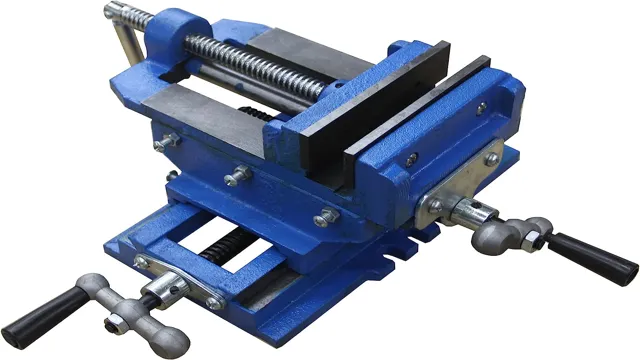

However, if you’re drilling a small, already secured piece, it may not be necessary to clamp it down. Additionally, if you’re using a drill press vise or hold-down clamp, you may not need to clamp your material separately. Ultimately, it’s important to assess each situation and make a judgement call on whether clamping is necessary for the safety of both you and your material.

Defining the Drill Press and Its Functions

A drill press, also known as a drilling machine, is a versatile tool used by carpenters, metalworkers, and mechanics to drill holes into various materials, including wood, metal, and plastic. The machine consists of a base, a motor, a drill head, and a chuck that holds the drill bit. The drill press can be used for a variety of tasks, such as drilling holes of different sizes and depths, countersinking, reaming, and tapping.

With the ability to adjust the drilling speed and depth, the drill press offers a precise and efficient way to make holes in different types of materials. Its versatility and accuracy make it an essential tool for any woodworking or metalworking shop. So if you are in the market for a new machine to help you with your drilling tasks, look no further than a drill press.

Exploring the Benefits of Clamping

Clamping is a technique used to hold objects tightly in place. It is a versatile tool that can be used in a variety of applications. Clamping is used in manufacturing to hold materials in place as they are being worked on.

This prevents the material from moving or shifting, which could cause errors in the finished product. Clamping is also used in construction to hold pieces together as they are being assembled. This ensures that the pieces are aligned correctly and that the finished product is structurally sound.

In this blog section, we will explore the different benefits of clamping and how it plays an important role in various industries.

When Clamping is Necessary

When it comes to drilling, clamping is not always necessary, but it can be extremely helpful. Whether you need to clamp on a drill press depends on the size and stability of the material you are drilling into. For small pieces of material, a clamp may not be needed since they can be held securely against the drill press table by hand.

However, for larger and more unstable materials, a clamp is necessary for safety reasons as well as accuracy. Using a clamp will prevent the material from moving around during drilling, reducing the risk of accidents. Additionally, a clamp will provide a more precise cut, making it easier to achieve the desired result.

Therefore, while you may not always need to clamp on a drill press, it is recommended to do so for larger and unstable materials to ensure both safety and precision in your drilling work.

Materials That Require Clamping

When working with certain materials, clamping is necessary to ensure a secure and accurate hold. Materials such as wood, metal, and plastic may require clamping during drilling, sawing, sanding, or other processes to prevent slipping or movement that can cause damage or inaccuracy. Clamps come in a variety of types, including C-clamps, bar clamps, and spring clamps, and choosing the right type depends on the specific project and materials being used.

Proper clamping can also help to reduce the risk of injury by keeping materials securely in place while working. So, if you want to ensure a perfect end result with your materials, it’s always best to use the appropriate clamping techniques to avoid mistakes and improve accuracy.

Safety Precautions When Clamping

When working with materials, there are often times when clamping is necessary to hold pieces together securely. However, it’s important to take proper safety precautions when using clamps to avoid any accidents. Firstly, always make sure to use the appropriate size clamp for the job and inspect it for any signs of damage before use.

Next, ensure that the clamp is securely and tightly fastened in place, using additional support if needed. When tightening the clamp, be cautious not to apply too much force as this may cause damage to the material or the clamp itself. It’s also important to keep your hands and fingers away from the clamping area at all times to prevent any injuries.

Finally, don’t forget to wear appropriate protective gear such as glasses or gloves to avoid any potential harm during the clamping process. Taking these safety measures will help ensure a successful and injury-free clamping experience.

How to Properly Clamp on a Drill Press

Clamping on a drill press is an essential task that ensures that your material stays secure while you drill. It is crucial to clamp down your workpiece when handling larger and heavier materials to prevent any potential accidents that may occur from the material shifting during the drilling process. When clamping, make sure that the clamps are placed firmly on the machine and the workpiece, and that the workpiece is placed as straight as possible to prevent misaligned holes.

Remember to always choose the right type of clamp for the job, as using the wrong type may cause damage to the material or the press. By properly clamping on a drill press, it is possible to achieve precise and efficient results, while also ensuring your safety in the process.

When Clamping is Not Needed

“Do you always clamp on a drill press?” is a commonly asked question by those new to using a drill press. While clamping is typically necessary for safety and accuracy, there are some situations where it may not be required. For example, drilling small holes into soft materials like foam or balsa wood may not require clamping.

Additionally, using a vise with built-in clamps may eliminate the need for additional clamping. However, it’s important to remember that clamping should always be used for larger or harder materials, as the drill bit can easily slip or bind if not properly secured. In short, while there may be instances where clamping is not necessary, it’s always better to err on the side of caution and use it whenever possible.

Materials That Do Not Require Clamping

When it comes to woodworking, clamping is essential for many projects. However, there are certain materials that do not require clamping, such as self-adhesive materials like veneers or wood tapes. These materials can be applied directly to the surface and do not need any extra pressure to adhere.

Additionally, some types of wood, like pressure-treated lumber or certain hardwoods, have a high enough natural density that they can be assembled without clamps. It is important to note that while clamping may not be necessary for these materials, it is still recommended to ensure a secure and stable joint. Always follow the manufacturer’s instructions and best practices for the specific materials you are using to achieve the desired results.

By knowing which materials do not require clamping, you can save time and effort on your woodworking projects while still achieving a professional finish.

Alternative Methods

Alternative Methods to traditional clamping techniques can be used when clamping is not necessary. For instance, adhesive-based solutions can be applied to temporarily bond materials together. This can come in handy in applications where the surface finish is a concern or when there is limited accessibility for clamping.

Additionally, mechanical methods like springs and magnets can be used to hold parts in place during the machining process. These methods provide an exceptional clamping force and can be utilized without requiring any additional tools or accessories. Moreover, vacuum clamping is an alternative method that utilizes negative pressure to clamp materials in place.

This option works best for delicate materials, such as thin metal sheets or glass, or when clamping deformable materials is not feasible. The flexibility of these alternative methods allows for more versatility during the machining process.

Conclusion

In conclusion, the answer to whether or not you should always clamp on a drill press is a resounding yes! Just remember that drilling without proper clamping is like trying to ice skate on a hot tub cover – it might seem like a good idea at first, but it’s sure to end in disaster. So go ahead and clamp it down, and let your drill press work its magic safely and efficiently.”

FAQs

Why is clamping important on a drill press?

Clamping is important on a drill press to ensure that the material being drilled stays in place and doesn’t move around, which can cause inaccurate holes or even injury.

Can you use any type of clamp on a drill press?

No, it’s important to use clamps that are specifically designed for use with a drill press to ensure safety and accuracy.

What are some common types of clamps used on a drill press?

Some common types of clamps used on a drill press include locking pliers, C-clamps, and quick-release clamps.

Is it possible to drill without clamping on a drill press?

It is technically possible, but it is not recommended as it can be dangerous and lead to inaccurate drilling.

Are there any materials that cannot be clamped on a drill press?

Yes, certain materials such as glass should not be clamped on a drill press as they can shatter under the pressure.

Can clamping affect the speed or power of the drill press?

No, clamping should not affect the speed or power of the drill press as long as it is done correctly.

How tight should you clamp the material on a drill press?

The material should be clamped tight enough to prevent movement but not so tight that it causes damage to the material or the drill press.