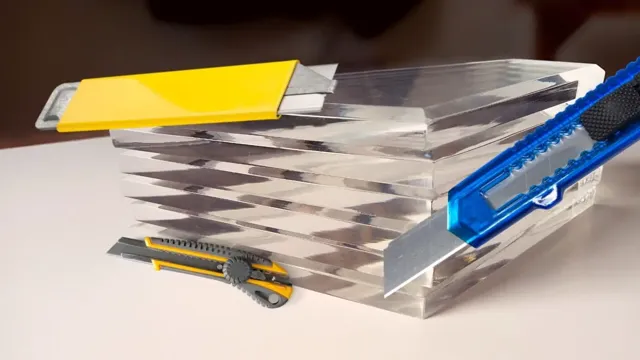

How Do You Cut Plexiglass with a Utility Knife? Tips and Tricks for Safe and Easy Cutting

Have you ever tried to cut plexiglass with a utility knife and ended up with a rough and uneven edge? Don’t worry, you’re not alone. Plexiglass, also known as acrylic glass, is a popular material for DIY projects, but it can be tricky to cut with precision. Using a utility knife is a cost-effective way to cut plexiglass, but it requires a bit of skill and patience.

In this blog, we’ll show you how to cut plexiglass with a utility knife like a pro, so you can create beautiful and professional-looking projects with ease. Let’s dive in!

Introduction

Cutting plexiglass with a utility knife might seem like a daunting task, but it is a lot easier than you might think. First things first, you will need a few supplies like a flat surface to work on, a ruler or straight edge, a marker, and of course, a sharp utility knife. Start by measuring and marking the plexiglass using the ruler and marker, ensuring that the markings are clear and accurate.

Then, clamp the plexiglass onto the flat surface to keep it steady and prevent it from moving. When using the utility knife, make sure to apply even pressure, be patient, and cut in a slow and steady motion. It’s essential to practice caution when working with plexiglass as it can crack or shatter if mishandled.

Overall, cutting plexiglass with a utility knife is a simple and easy process that only requires a few tools and a bit of patience.

What is Plexiglass?

Plexiglass is a type of acrylic glass that is highly transparent, sturdy, and lightweight. It is a synthetic polymer made of methyl methacrylate, which is commonly known as MMA. Plexiglass is widely used in various industries, such as construction, automotive, medical, and aerospace.

Due to its excellent clarity and transparency, plexiglass is often used as a substitute for traditional glass. It is also known for its shatter-resistant properties, making it a safer option than regular glass. Moreover, plexiglass is relatively easy to cut, shape, and drill, which makes it a versatile material for different applications.

As a result, plexiglass is becoming increasingly popular, and its demand is on the rise.

Why Use a Utility Knife?

As DIY enthusiasts or homeowners, having the right tools for the job can make all the difference. One such tool that can significantly aid in various projects is a utility knife. A utility knife is a versatile cutting tool that is ideal for a variety of tasks, including cutting through cardboard, slicing through plastic, and opening packages.

Its compact size and simple design make it easy to use, even with one hand, and the razor-sharp blade ensures a clean and precise cut every time. Using a utility knife can save you time and effort in your projects, and the convenience it provides can make it a valuable addition to your tool collection.

Preparing Your Work Area

When cutting plexiglass with a utility knife, it is essential to prepare your work area properly. You should have plenty of space to move around and work comfortably. It is also crucial to ensure that the surface underneath the plexiglass is sturdy and flat.

If you are working on an uneven surface, you could end up damaging the plexiglass or injuring yourself. To prevent this, place a piece of wood or another flat surface underneath the plexiglass before you begin cutting. Additionally, make sure you have all the necessary tools and safety equipment within reach.

This includes a sharp utility knife, a straight edge or ruler, and safety goggles or glasses. By preparing your work area thoroughly, you can ensure a safe and successful outcome when cutting plexiglass with a utility knife.

Gather Necessary Supplies

When preparing your work area for your project, it’s important to gather all the necessary supplies beforehand. This not only saves you the hassle of having to stop in the middle of your work to search for missing items but also helps you stay organized and focused on the task at hand. First and foremost, make sure you have all the tools required for your project, such as scissors, knives, measuring tape, and brushes.

Then, stock up on materials such as paint, glue, tape, or whatever else your project requires. Before you begin, clear your work area of any clutter or distractions and make sure you have enough space to move around comfortably. A clutter-free and well-lit work area not only helps you be more productive but also ensures your safety.

Remember, the more prepared you are, the smoother and more enjoyable your project will be.

Secure Plexiglass for Cutting

When it comes to cutting plexiglass, it’s essential to have a safe and secure work area. One of the best ways to do this is by using a plexiglass cutting table that has a secure Plexiglass sheet attached. This sheet will not only protect your work surface but also ensure your safety while cutting.

By preventing any shards from flying off, it helps to eliminate the risk of injury. Before you start cutting, make sure your work area is clean and free of any debris. This will ensure that your materials won’t become damaged, which could potentially lead to injury.

It’s a good idea to also use a dust mask to prevent inhaling any airborne particles. Once you have your work area prepared, it’s time to secure the Plexiglass sheet. You can do this by clamping it tightly to your cutting table.

Another way to secure the sheet is to use double-sided tape or adhesive to attach it to the table. This method is especially useful if you don’t have any clamps at your disposal. By taking the time to prepare your work area and secure your Plexiglass sheet, you’ll have peace of mind while cutting.

You can focus on creating the perfect cut without worrying about any injuries or damage to your materials. Remember, safety always comes first when working with any materials, and that includes plexiglass.

Marking the Cut Line

One important step when cutting plexiglass with a utility knife is marking the cut line. This can be done using a marker or masking tape applied to the surface of the plexiglass. Make sure to measure and mark the desired cut before doing anything else.

It’s also important to choose the right type of blade for your utility knife. A sharp blade with a pointed tip is ideal for scoring the plexiglass along the marked cut line. Score the surface several times with firm pressure before snapping the plexiglass along the scored line.

Remember to use protective gear, such as gloves and safety glasses, to prevent injury during the cutting process. With the right technique and tools, cutting plexiglass with a utility knife can be a straightforward and rewarding DIY project.

Measure and Mark the Plexiglass

Before you start cutting your plexiglass, you’ll need to mark a cut line. This will ensure that you get a precise cut and don’t end up damaging your material. The first step is measuring your plexiglass carefully using a tape measure or ruler.

Once you have your measurements, use a pencil to mark the cut line on both sides of the plexiglass. Make sure the line is straight and even. You can use a straightedge or ruler to help guide your line.

It’s important to note that if you’re using a circular saw or jigsaw, you’ll need to also mark where you want to make your entry and exit cuts. This will prevent the plexiglass from breaking or cracking during the cutting process. With these tips in mind, you’ll be ready to start cutting your plexiglass with accuracy and precision.

Use a Straight Edge for Accuracy

When it comes to woodworking, accuracy is key. One great way to ensure that your cuts are precise and straight is by using a straight edge. A straight edge is a flat, straight tool that can be used to create a perfectly straight line.

To mark your cut line, simply place the straight edge where you want the cut to be made and then draw your line along the edge. This will ensure that your cut is straight and accurate, which is especially important if you are creating a piece that needs to fit together perfectly. When using a straight edge, always make sure that it is securely in place before making your cut.

A slight shift in the tool can greatly impact the accuracy of your cut. Therefore, take your time, double-check your measurements, and use a clamping device to secure the straight edge in place. With a little bit of patience and the right tools, you can create straight and precise cuts every time.

So, don’t be afraid to take your time and invest in a good straight edge to make your woodworking projects really stand out.

Cutting the Plexiglass

When it comes to cutting plexiglass, using a utility knife is a popular method. To start, make sure you have the proper safety gear, such as gloves and eye protection. Then, use a straightedge to mark the line where you want to make the cut.

Next, score the plexiglass along the marked line with a utility knife. Apply firm pressure, but avoid pressing too hard or you may crack the plexiglass. Once the plexiglass is scored, gently snap it along the scored line to complete the cut.

Keep in mind that this method works best for thinner plexiglass sheets, and for thicker sheets, a saw may be necessary. Overall, cutting plexiglass with a utility knife is a simple and cost-effective solution that allows for precise cuts with a little bit of practice.

Score the Plexiglass With a Utility Knife

Cutting plexiglass can be a bit intimidating, but with the right tools and technique, it’s actually quite easy. One of the best ways to cut plexiglass is by scoring it with a utility knife. Start by marking your cutting line with a permanent marker.

Then, clamp the plexiglass securely to a work surface to prevent any movement while cutting. Using a utility knife, score along the marked line several times, applying even pressure each time. Make sure to use a sharp blade and replace it frequently to ensure clean cuts.

After scoring, you can snap the plexiglass along the scored line or use a saw to finish the cut. With this simple method, cutting plexiglass can be a breeze.

Cut Along the Score Line

When it comes to cutting plexiglass, it’s important to pay attention to the score line. This is the area that has been specifically marked to make it easier for you to cut through the material without chipping or cracking it. To get started, take a sharp knife or glass cutter and apply firm pressure to the score line.

Don’t try to cut through the plexiglass all at once, but rather take your time and make several passes until the material is completely cut through. Once you’ve made the cut, be sure to clean up any rough edges with sandpaper or a file. Remember, cutting plexiglass can seem daunting at first, but with the right tools and technique, it’s a straightforward process.

So go ahead and give it a try, you might be surprised at how easy it is to get a clean cut.

Finishing the Cut Edge

If you’re wondering how to cut plexiglass with a utility knife, it’s important to know that it is possible but requires patience, caution, and a steady hand. Firstly, measure and mark the plexiglass with a ruler and a fine-tipped marker or grease pencil. Then, score the plexiglass along the marked line using a utility knife and a straight edge as a guide.

Be sure to cut only halfway through the thickness of the plexiglass to avoid cracking or chipping. Continue scoring along the line until the cut is completed. After cutting, use sandpaper or a sanding block to smooth out any rough edges.

This will create a clean and finished edge that won’t scratch or catch on things. Remember, always wear protective gear like gloves and goggles when cutting or handling plexiglass to avoid injury.

Sand the Cut Edge of the Plexiglass

After cutting plexiglass, the edges can be rough or jagged, and that’s where sanding comes in. Sanding the cut edge of plexiglass is essential to provide a smooth and even finish. To begin the process, use a low grit sandpaper such as 220 grit to remove any rough edges.

Use light pressure and sand in a circular motion until the edge is even. Then, switch to a higher grit sandpaper, such as 400 grit, and repeat the process. The higher grit sandpaper will further refine the edge, leaving it smooth and ready for use.

It is crucial to take your time and check frequently to ensure that the edge is even. Otherwise, any roughness will be immediately visible after installation. With a little patience and effort, sanding your plexiglass edge will give you a professional, polished look for your project.

Smooth Out Any Rough Edges

When it comes to cutting fabric, it’s important to smooth out any rough edges to create a clean and neat finish. There are a few different tools you can use to achieve this, including a serger, a zigzag stitch on a sewing machine, or even just a pair of pinking shears. The goal is to prevent the fabric from fraying or unraveling and to give it a polished look.

Once you’ve finished cutting your piece, take a few extra minutes to tend to any rough spots along the edges. This additional step may seem small, but it can make a big difference in the final product. So go ahead and take the time to smooth out those edges, and you’ll be rewarded with a professional-looking finished product.

Conclusion

Cutting plexiglass with a utility knife can be a daunting task. But with the right technique and a little patience, you can easily slice through this transparent material like a hot knife through butter. Just remember, slow and steady wins the race when it comes to plexiglass.

So take your time, keep your blade sharp, and enjoy the satisfaction of a job well done. And always remember, when life gives you plexiglass, make something amazing out of it!”

FAQs

What safety precautions should be taken before cutting plexiglass with a utility knife?

Before cutting plexiglass with a utility knife, you should wear safety goggles and gloves to protect your eyes and hands.

Is a utility knife the best tool to use for cutting plexiglass?

A utility knife can be used for cutting thin plexiglass, but for thicker sheets, specialized tools such as a circular saw or jigsaw may be more effective.

What is the proper technique for cutting plexiglass with a utility knife?

To cut plexiglass with a utility knife, score the sheet multiple times along the cut line, applying moderate pressure. Then, slowly bend the sheet along the cut line until it snaps apart.

Can you reuse a utility knife blade for cutting plexiglass?

It is not recommended to reuse a utility knife blade for cutting plexiglass, as the blade can become dull or damaged, leading to poor cuts and potentially dangerous situations.

How do you prevent cracking or chipping when cutting plexiglass with a utility knife?

To prevent cracking or chipping when cutting plexiglass with a utility knife, use a straight edge as a guide to keep the cut straight and apply light pressure to the sheet while scoring to avoid excess stress on the material.

What is the best way to clean plexiglass after it has been cut with a utility knife?

To clean plexiglass after cutting with a utility knife, use a soft, lint-free cloth and a mild soap solution. Avoid using abrasive cleaners or rough cloths, as they can scratch the surface.

Can you recycle plexiglass scraps after cutting with a utility knife?

Yes, plexiglass scraps can be recycled by contacting specialized recycling centers or facilities that accept plastic materials.