How Do You Use a Drill Press Safely? Essential Tips and Precautions to Follow

Have you been itching to tackle a new DIY project but are intimidated by the equipment? Using a drill press can be daunting, but with proper know-how and safety precautions, it can become your go-to tool for all future projects. In this blog, we will discuss the essential measures you need to take to ensure that you are Using A Drill Press Safely. We’ll go over everything from protective gear to machine maintenance to guarantee that you can drill with confidence and without injury.

So grab your safety goggles, and let’s get started!

Introduction: Importance of Safety

Using a drill press improperly can be dangerous. That’s why it’s essential to know how to use it safely. Before starting, it’s important to read the manual so you can familiarize yourself with the machine.

Make sure to wear appropriate personal protective equipment (PPE), including eye protection and gloves. Position the workpiece securely on the drill press table and adjust the depth stop to prevent going too deep. Make sure to set the speed appropriately for the drill bit being used and the material being drilled.

When drilling, keep your hands, clothing, and hair away from moving parts. Never leave the drill press running unattended, and always turn off the machine and unplug it before making any adjustments or changing the drill bit. Using a drill press correctly is crucial for your safety and the quality of your work.

So, be sure to follow these guidelines and take your time to ensure a job well done.

Understanding the Drill Press

When it comes to operating a drill press, safety should always be the top priority. It’s important to remember that this machine can cause serious injuries if not used properly. Before even turning on the press, it’s essential to wear the right protective gear, including safety goggles, gloves, and earplugs.

Next, it’s crucial to make sure the drill press is properly installed and secured before use. This includes checking the table height, adjusting the belt tension, and making sure the chuck is securely tightened. When you’re ready to start drilling, be sure to keep your hands and loose clothing away from the moving parts.

Regular maintenance and inspections should also be conducted to ensure the drill press is in good working order. Remember, taking the necessary safety precautions is key to success when operating a drill press.

Wearing Proper Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) Safety should always be a top priority in any workplace, and one way to ensure it is by wearing proper personal protective equipment (PPE). PPE includes gear such as hard hats, safety goggles, gloves, face masks, and safety shoes, among others. Wearing it can help prevent injuries and illnesses caused by exposure to hazardous substances, physical accidents, and other workplace hazards.

PPE is crucial for protecting workers from harm in various industries, including construction, healthcare, manufacturing, and transportation. By donning the right PPE, workers can perform their duties with confidence, knowing that their health and wellbeing are being looked after. However, it’s essential to note that PPE is not a substitute for other safety measures, and proper training on how to wear and use it is also necessary.

Overall, investing in proper PPE can make a significant impact on employee safety and productivity.

Preparing to Use a Drill Press

When it comes to using a drill press, safety is of utmost importance. Before using the machine, it is essential to prepare the work area. Make sure there is enough space around the drill press for the operator and the material being drilled.

Secure the material firmly to the table, and check that the drill bit is properly installed and tightened. It is also crucial to wear appropriate personal protective equipment, including safety goggles and hearing protection. Make sure the drill press is turned off before plugging it in, and double-check that the power cord is in good condition and not frayed.

Once everything is set up, turn on the drill press and gradually increase the speed to the desired level. Always keep your hands and the material away from the drill bit while it is spinning, and avoid wearing loose clothing or jewelry that could get caught in the machine. By following these guidelines and taking the time to properly prepare and use the equipment, you can safely execute precise and efficient drilling operations.

Inspecting Your Drill Press

Preparing to use a drill press requires some preparation. The first step involves inspecting your drill press before use. Start by checking if it’s level and stationary; if it wobbles, it will cause inaccuracies in the hole you drill.

Next, check the table for squareness to the chuck and also the table’s holding power against jump. Make sure the belts are properly tensioned and in good condition, and finally, ensure the chuck’s jaws are tight around the drill bit. All these checks are crucial in maintaining a safe and accurate drill press.

By taking the time to inspect and prepare your drill press, you can avoid inaccurate drilling, and most importantly, keep yourself safe from harm.

Securing Your Workpiece

When preparing to use a drill press, one of the most important aspects to consider is securing your workpiece. This is essential to prevent accidents, maintain accuracy, and achieve the desired outcome. There are different ways to do this depending on the size, shape, and material of the workpiece.

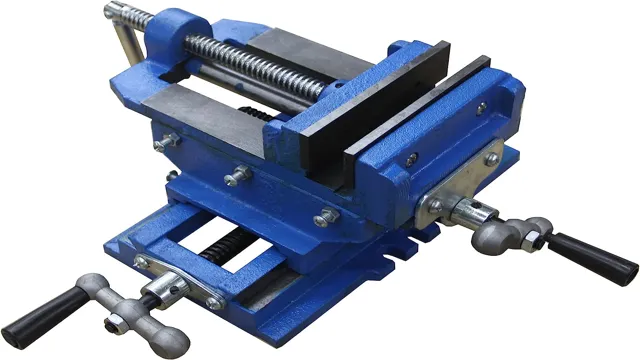

One common method is to use clamps, which can hold the workpiece firmly in place and also allow for easy adjustments. It’s important to position the clamps away from the drilling area to avoid interfering with the bit and to use as many clamps as needed to ensure stability. Another option is to use a vise, which is a specialized clamp that is designed to grip objects with more force and precision.

A vise can be mounted on the table or attached to the drill press itself, depending on the model. Regardless of the method you choose, it’s important to test the stability of the workpiece before starting to drill to ensure that it doesn’t move or wobble during the process. By taking the time to properly secure your workpiece, you can improve your safety, efficiency, and results, making your time with a drill press more productive and enjoyable.

Adjusting the Depth Stop and Table Height

When it comes to using a drill press, ensuring the right depth and table height is essential to produce precise and accurate drill holes. To do this, the depth stop and table height must be adjusted accordingly. Start by loosening the bolts on the depth stop, then slide it up or down to the desired depth before locking it back in place.

The table height can be adjusted by loosening the bolts underneath the table and raising or lowering it to the desired height. Always make sure that the table is level before starting to drill. By taking the time to properly adjust the depth stop and table height, you can ensure that your drill holes are consistent in depth and placement, making your work much more efficient and professional-looking.

Remember, accuracy is key to a successful project, and investing in a good drill press can help you achieve just that.

Using a Drill Press carefully

If you’re looking for the most efficient and precise way to make holes in your woodworking projects, a drill press is the perfect tool for you. However, it’s important to understand that using a drill press safely requires some precautions and knowledge. First and foremost, make sure to secure the workpiece tightly to the drill press table using clamps.

Also, position the table and drill bit appropriately before turning on the machine. Another important aspect is the use of proper safety equipment such as safety glasses, earplugs, and a dust mask. When operating the drill press, apply steady and even pressure, avoid overfeeding the drilling bit and keep your hands away from the chuck and moving parts.

By following these guidelines, anyone can safely and successfully operate a drill press. So, if you’ve been wondering, “How do you use a drill press safely?” now you know!

Starting and Stopping the Drill Press

When using a drill press, it’s important to start and stop it carefully to avoid any accidents or damage to the machine. Always make sure that the drill bit is securely in place before starting and be sure to adjust the speed and depth of the drill according to the material being drilled. When stopping the drill, turn off the machine first and then release the pressure on the drill bit before removing it.

Remember, the drill press is a powerful tool and should be used with caution to ensure safe and efficient operation. By following proper procedures and taking your time, you can achieve precise and accurate results without any mishaps. So, take your time and remember safety first.

Holding Your Workpiece and Using the Spindle

When it comes to using a drill press, it’s crucial to be careful. Holding your workpiece steady is essential to avoid any accidents. The best way to do this is by using clamps, a vise or even a holding jig.

Be sure to secure your workpiece firmly onto the drill press table to prevent it from moving around. Remember, a slipping workpiece can lead to disastrous results and even cause injury. Once your workpiece is secure, it’s time to adjust the spindle to the correct speed for your specific task.

Setting the speed too fast can cause overheating, while too slow can cause your drill bit to break. Finally, be mindful of the spindle’s direction of rotation. It’s important to make sure the spindle rotates in the proper direction, or else your drill bit won’t be able to cut through the material.

By paying attention to these details and taking your time, you can use a drill press safely and effectively, leading to accurate and precise results.

Avoiding Common Hazards

Using a drill press can be a convenient and efficient way to drill precise holes in a variety of materials. However, it’s important to use the drill press carefully to avoid common hazards. First and foremost, always wear appropriate safety gear, including eye protection and gloves.

Additionally, make sure the workpiece is securely clamped down to prevent it from moving during drilling. It’s also important to select the appropriate speed and drill bit for the material being drilled, as using the wrong speed or bit can lead to overheating, breakage, or other issues. Finally, be aware of the potential for the drill bit to bind or catch in the material, which can cause the workpiece to spin or even break.

By taking these precautions and using a drill press carefully, you can ensure safe and accurate drilling for all your projects.

Conclusion and Additional Tips

In conclusion, using a drill press safely involves a combination of preparation, technique, and common sense. Just like driving a car, you need to be aware of your surroundings, follow the rules, and use caution at all times. Remember to select the right drill bit, secure your workpiece, adjust your speed and depth, and always wear eye protection.

And most importantly, never underestimate the power of a sharp beaver…

I mean, drill bit.”

FAQs

What should you wear when using a drill press?

It’s important to wear eye protection, ear protection, and sturdy closed-toe shoes when operating a drill press to prevent injury.

How should you prepare the workspace before using a drill press?

Clear the area around the drill press of any clutter and ensure that the drill press is properly mounted to a sturdy workbench or stand.

What safety features should you look for when purchasing a drill press?

Look for a drill press with a safety shield to protect your eyes and hands from debris, a table that can be adjusted for height and angle, and a stop button for emergencies.

Can you use a drill press to drill any material safely?

No, certain materials like glass or brittle plastics should not be drilled with a drill press without proper safety precautions or specialized equipment.

How should you maintain your drill press to ensure safe and effective use?

Regularly inspect and clean the drill press, replace any damaged or worn parts, and follow the manufacturer’s recommended maintenance schedule.

What should you do if your drill bit becomes stuck in the material you are drilling?

Stop the drill press immediately, turn off the power, and use pliers or another tool to extract the stuck bit.

How can you ensure that your drill bit is securely fastened in the chuck before use?

Always tighten the chuck firmly around the drill bit using the chuck key until it cannot be turned any further by hand.