How Does a Drill Press Spindle Work: A Comprehensive Guide for Beginners

Have you ever wondered how a drill press spindle works? It’s actually a fascinating process that involves different mechanical components working together seamlessly. The spindle is an essential part of a drill press, and it’s responsible for holding the drill bit securely in place while it rotates. At its core, the spindle is essentially a rotating shaft that holds the drill bit at the end.

The spindle is mounted on the top of the drill press, and it’s driven by a motor that rotates the shaft at high speeds. The drill bit is inserted into a chuck, which is attached to the end of the spindle. The chuck is tightened around the drill bit, ensuring it’s firmly in place and won’t wobble during operation.

The spindle also contains other vital components, such as bearings, that help reduce friction while the spindle rotates at high speeds. These components work together to ensure smooth operation and precise drilling. When you turn on the drill press, the motor rotates the spindle and the drill bit attached to it.

As the drill bit starts to drill into the material, the spindle helps keep it stable and centered. This allows for accurate drilling without any unwanted drifting or wobbling. In conclusion, the drill press spindle is a critical component that plays a significant role in the drill press’s overall functionality.

Understanding how it works can help you make better use of your drill press and achieve more accurate and precise drilling results.

Overview of Drill Press Spindle

The drill press spindle is a crucial component of a drill press machine that holds and rotates the drill bit. It is typically made up of a hollow metal tube that is mounted vertically on the drill press column and attached to a motor at the bottom via a pulley system. The spindle is driven by the motor, which powers the rotation of the chuck that holds the drill bit.

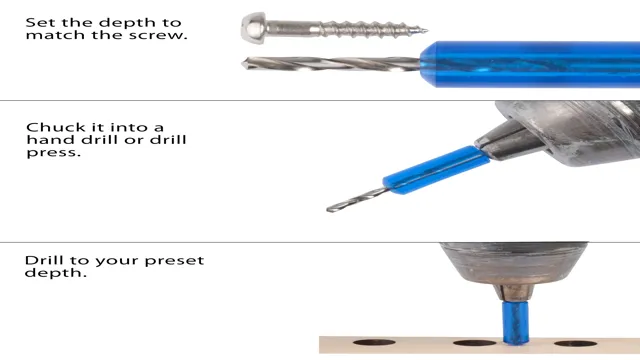

When the machine is turned on, the operator pulls the drill bit down onto the material they want to drill through. As the spindle rotates, the drill bit makes contact with the material, and the friction chips away at the surface until a hole is made. The drill press spindle allows users to control the speed and depth of the drilling process, making it an essential tool for precision drilling.

It is crucial to ensure that the spindle is always in top condition and properly maintained to ensure the quality of the drilling process.

Components of a Drill Press Spindle

A drill press spindle is an essential part of any drill press machine. It is the component that houses the chuck, which holds the bit securely in place when drilling. The spindle is made up of several main components: the quill, the spindle sleeve, the bearing assembly, and the chuck.

The quill is the hollow tube that surrounds the spindle and provides a guide for it to move vertically up and down. The spindle sleeve is the portion of the spindle that extends from the quill and holds the chuck. The bearing assembly supports the spindle and allows it to rotate smoothly.

Finally, the chuck is the component that holds the drill bit and allows it to rotate with the spindle as it drills into the material. These components work together to ensure precision and accuracy when drilling, providing the user with a reliable and efficient tool for the task at hand.

How the Spindle Rotates

The spindle of a drill press is what makes the tool so powerful and versatile. Essentially, the spindle is the part of the drill press that rotates, allowing the drill bit to move through the material being worked on. Most drill press spindles are powered by a motor, which drives the rotation of the spindle via a belt or gear mechanism.

The speed of the spindle can be adjusted to the needs of the project, and the direction of rotation can be reversed if necessary. It’s important to note that the spindle is typically made out of a high-quality material, such as steel, to ensure it can withstand the heat and pressure generated by drilling. Without a sturdy spindle, a drill press would not be a reliable or effective tool.

So, if you’re looking to take on some serious DIY or professional projects, pay attention to the quality of the spindle and make sure it can stand up to the task at hand.

Types of Drill Press Spindles

When it comes to drill presses, the spindle is the part that holds the drill bit in place and rotates it to create holes in a workpiece. There are different types of drill press spindles, each designed for specific tasks. The most common type is the standard spindle, which has a chuck that can hold a range of different drill bit sizes.

Some spindles are designed for larger bits and have a morse taper or a jacobs taper. Others are made to accommodate more delicate work, such as the quill spindle, which has a soft grip chuck for precision drilling. Regardless of the type, all drill press spindles work by rotating the drill bit at varying speeds to achieve the desired hole size and depth.

So when you’re selecting a drill press for your needs, it’s important to consider the spindle type and its capabilities.

Fixed vs. Adjustable Spindle

When it comes to drill presses, there are two types of spindles to consider: fixed and adjustable. A fixed spindle is set at a specific depth and cannot be adjusted. This is ideal for jobs that require consistent, repetitive drilling.

On the other hand, an adjustable spindle can be moved up or down depending on the material being drilled. This allows for more versatility in the types of jobs that can be tackled with a drill press. Adjustable spindles are also useful when drilling through varying thicknesses of materials, as the spindle can be adjusted to match the thickness of the material.

Ultimately, the type of spindle you choose will depend on the types of jobs you need to complete with your drill press. Whether you opt for a fixed or adjustable spindle, be sure to choose a high-quality drill press that will provide consistent, reliable performance.

Keyed vs. Keyless Chuck Spindle

When choosing a drill press, one of the most critical decisions to make is which type of spindle to opt for: keyed or keyless. A keyed spindle requires the use of a chuck key to tighten and loosen the drill bit, whereas a keyless spindle utilizes a hand-tightened mechanism to secure the bit in place. A keyless spindle offers greater convenience as it does not require a separate tool to adjust the drill bit’s tightness.

Whereas, a keyed spindle generally provides the user with a higher level of precision, as it typically has fewer moving parts and tighter tolerances. It’s important to consider the type of projects you’ll be working on to determine which spindle is the best fit for you. If you require precise drilling operations, such as drilling through metal or woodwork, a keyed spindle might be the best option.

Alternatively, if you frequently switch between different drill bits and materials, a keyless chuck spindle may be a more suitable choice. Ultimately, both keyed and keyless spindles have their pros and cons, and the choice comes down to personal preference and the nature of the projects at hand. Whatever you decide, make sure to take the time to understand the differences and choose the spindle that best suits your specific needs and requirements.

Conclusion

In the world of power tools, the drill press spindle is the ultimate multitasker. It spins, it twists, and it bores into just about anything you can imagine. But how does it work? Well, it’s a bit like a marriage, really.

The spindle is the heart of the drill press, and it’s the one that does all the heavy lifting. It’s supported by a sturdy column that keeps it steady and straight, just like a partner who’s always there to lend a hand. And when the going gets tough, it’s the spindle that takes the brunt of the force, just like a spouse who’s always willing to go the extra mile.

In short, the spindle is the unsung hero of the drill press, quietly doing its job with precision and power, while the rest of the tool gets all the attention. So the next time you’re using a drill press, take a moment to appreciate the spindle that’s working tirelessly behind the scenes – it truly is a marvel of engineering and ingenuity.”

FAQs

What is a drill press spindle and how does it work?

A drill press spindle is a rotating shaft that holds the drill bit in place on a drill press. It works by rotating the drill bit at high speeds to bore holes into a variety of materials.

Can drill press spindles be replaced or repaired if they break?

Yes, drill press spindles can be replaced or repaired if they break. Replacement spindles can be purchased and installed by a professional, or DIY repair kits can be used to fix minor damage.

How fast do drill press spindles rotate?

The speed at which a drill press spindle rotates can vary depending on the model and settings, but most can reach speeds of up to 3,000 RPM (rotations per minute).

Can drill press spindles accommodate different types of drill bits?

Yes, most drill press spindles can accommodate a variety of drill bits, including standard twist bits, spade bits, and hole saws.

How can I maintain and extend the lifespan of my drill press spindle?

Regular cleaning and maintenance can help extend the lifespan of your drill press spindle. This includes keeping it lubricated, inspecting it for damage or wear, and following manufacturer recommendations for use and care.

Are drill press spindles compatible with all drill presses?

No, drill press spindles are not necessarily compatible with all drill presses. It’s important to ensure that the spindle you choose is compatible with your specific drill press model.

Can drill press spindles be used for other types of drilling applications, such as metalworking or woodworking?

Yes, drill press spindles can be used for a variety of drilling applications, including metalworking and woodworking. However, it’s important to use the appropriate drill bits and settings for the specific material you’re working with.