How Does a Jackhammer Work: The Complete Guide to Power and Precision

Have you ever seen a jackhammer at work and wondered how it manages to break through solid concrete with such ease? It’s a magnificent machine that uses power and technology to deliver powerful punches repeatedly and with great speed. In this blog post, we’ll take a closer look at how a jackhammer works and the science behind it. A jackhammer, also known as a demolition hammer or pneumatic drill, is a powerful tool designed to break through hard surfaces such as roads, concrete walls, and rocks.

It works on a simple principle of applying high-frequency force from a piston to a chisel-like bit to create an impact that breaks apart the surface. The process starts with a compressor or air tank that generates high-pressure air. This compressed air is then transferred through a hose into a cylinder that contains a piston.

The piston moves back and forth at high speed, generating a powerful force and pressure on one end of the cylinder. The other end of the cylinder houses a chisel-like bit that is designed to break the surface. The force is transferred from the piston through a hammer and to the bit, which delivers the impact.

This process repeats, with each impact breaking more and more of the surface until the required depth is reached. Of course, there’s more to it than that, and we’ll explore the finer details in our next post. Stay tuned to discover the complexities and intricacies of how a jackhammer works, and how technology and engineering combine to provide a powerful tool in the construction, demolition, and excavation industries.

Overview

If you’ve ever seen a jackhammer in action, then you know how effective it can be in breaking up concrete and rocks. But have you ever wondered how a jackhammer actually works? To put it simply, a jackhammer works by using compressed air to create a powerful force that pounds against the surface it’s placed on. Inside the jackhammer, there is a piston that moves back and forth quickly, creating a steady stream of air that becomes trapped in the cylinder.

This trapped air creates pressure that forces the piston downward, and when the piston reaches the bottom of its stroke, it releases the compressed air, which then drives the chisel at the end of the jackhammer back and forth. This process repeats itself rapidly, causing the chisel to break up whatever surface it’s placed on. Overall, a jackhammer is a powerful tool that relies on the science of pneumatic pressure to get the job done.

Parts and Components

When it comes to electronic devices, parts and components play an essential role in determining the device’s quality and functionality. These parts are the building blocks of any device and come in different shapes and sizes. Each part is designed to perform specific functions and can be replaced if necessary.

Some of the most common parts found in electronic devices include resistors, capacitors, diodes, transistors, and integrated circuits. All these parts work together to ensure the device operates as intended. For instance, a capacitor stores electrical energy and releases it when required, while a diode allows the flow of current in one direction only.

Without these parts, the device would not operate correctly or will not operate at all. For this reason, it’s essential to choose high-quality components to ensure longevity and prevent any potential breakdowns. As such, it’s crucial to understand the specific function of each part and select them accordingly to build the device you want.

Mechanism of Action

The mechanism of action of a drug is the process by which it exerts its therapeutic effects on the body. This can be a complex process involving a number of different pathways, but ultimately it boils down to how the drug interacts with specific target molecules in the body. Depending on the drug in question, this could involve binding to enzymes, receptors, ion channels, or other cellular components to produce a desired effect.

For example, antidepressants work by blocking the reuptake of certain neurotransmitters in the brain, while antibiotics inhibit bacterial cell wall synthesis. In general, drugs that are highly specific in their binding are more effective and have fewer side effects than those that bind more broadly. Understanding the mechanism of action is essential for developing new drugs and improving existing ones, as well as for predicting potential side effects and drug interactions.

Power Source

If you’ve ever witnessed or used a jackhammer before, you might be wondering, “how does a jackhammer work?” The answer lies in its power source, which is an air compressor. Compressed air is forced into the jackhammer through a hose and into a chamber where it drives a piston back and forth, which in turn drives a chisel or point attached to the hammer’s business end. The repetitive cycling of the piston produces a rapid succession of impacts, which can break through rock, concrete, and other types of hard surfaces.

The intensity of the force can be adjusted depending on the job, making jackhammers versatile tools for demolition, excavation, and construction work. While the process might seem simple, the incredible power generated by a jackhammer is what makes it an essential tool for those in the construction industry.

Electric Jackhammers

When it comes to electric jackhammers, the power source is a crucial factor to consider. Most electric jackhammers are powered by either electricity or batteries. Electric-powered jackhammers are usually favored by professionals for their high levels of power and consistent performance.

They are connected to a power outlet, making them more reliable than battery-powered options. On the other hand, battery-powered jackhammers offer more mobility and flexibility, as they are not restricted by cords or power outlets. However, they have limited power and runtime, which may not be suitable for large-scale projects.

Ultimately, the choice between an electric or battery-powered jackhammer comes down to personal preference and the demands of the project at hand.

Pneumatic Jackhammers

Pneumatic Jackhammers When it comes to power sources for pneumatic jackhammers, compressed air reigns supreme. Compressed air is an incredibly versatile and efficient power source that can deliver immense force for extended periods without overheating. One significant advantage of using compressed air is that it is widely available on most job sites, making it a popular choice for construction workers, demolition crews, and other industrial professionals.

Compressed air also offers reliable and consistent performance, allowing users to accomplish heavy-duty tasks effectively and efficiently. While electric jackhammers require a steady source of power, often limiting their mobility, pneumatic jackhammers can easily be transported and used on different job sites with ease. Therefore, pneumatic jackhammers powered by compressed air offer a robust and reliable power source, making them a favorite choice for professionals in a wide range of industries.

Hydraulic Jackhammers

When it comes to hydraulic jackhammers, the power source is a highly important aspect to consider. These powerful tools require a strong and reliable power source to operate effectively, and there are several options available for users to choose from. The most common power source for hydraulic jackhammers is an external hydraulic power pack, which provides the necessary pressure and flow of hydraulic oil to power the jackhammer.

Other options include electric power sources and gasoline or diesel-powered engines. Each power source has its own advantages and disadvantages, depending on the specific needs and requirements of the user. For example, electric-powered hydraulic jackhammers are quieter and more eco-friendly, while gasoline or diesel-powered jackhammers provide greater mobility and flexibility in remote areas where electrical outlets may not be readily accessible.

Ultimately, the choice of power source will depend on a variety of factors, such as the job site conditions, the required power output, and the user’s personal preferences. Regardless of the power source chosen, it is important to ensure that it is reliable and able to provide the necessary power to get the job done efficiently and effectively.

Safety Tips

If you’ve ever seen a construction crew or road workers at their job, you’ve likely seen a jackhammer in action. But how exactly does this powerful machine work? Jackhammers, also known as pneumatic drills, use compressed air to create powerful upward and downward motions. This allows the machine to break up concrete, pavement, and other hard surfaces with ease.

The piston inside the jackhammer moves up and down rapidly, striking the tip of the chisel or bit attached to it. This high-speed impact is what allows the tool to break up even the toughest materials. Jackhammers can be dangerous if not used properly, so always make sure to follow safety procedures and wear appropriate gear, such as earplugs and goggles.

Wear Protective Gear

When taking part in any sports activity or physical exercise, it’s important to wear protective gear to prevent any injuries. This can include helmets, knee and elbow pads, gloves, and other specially designed equipment. These items can help protect you from concussions, broken bones, and other injuries that can occur during falls or collisions.

While some people may feel that protective gear is unnecessary, the reality is that accidents can happen to anyone at any time. It’s always better to be safe than sorry. So, before you hit the field or head out on your bike, make sure you’re properly equipped with the right gear.

By doing so, you’ll not only be protecting yourself, but also ensuring that you can continue doing something you love for years to come.

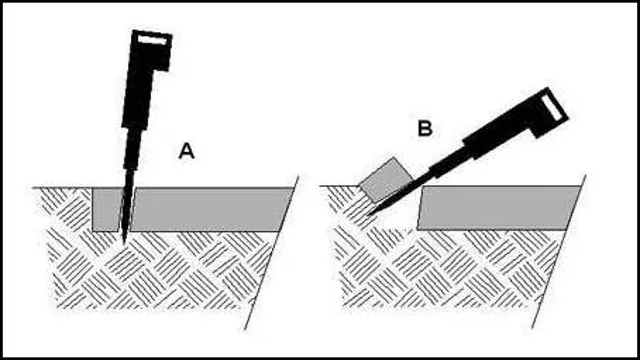

Proper Use and Positioning

Properly using and positioning equipment is crucial to ensuring safety while working. Whether it’s operating machinery or using tools, improper usage or positioning can lead to accidents and injuries. It’s essential to follow the manufacturer’s instructions, use safety equipment such as goggles or gloves, and position yourself in a way that allows you to have control over the equipment.

Always make sure the equipment is in good working condition before using it and take breaks when necessary to avoid fatigue or distraction. Remember, safety should always be your top priority when working with equipment. By following these safety tips and using the equipment properly, you can reduce the risk of accidents and injuries.

Conclusion

In conclusion, a jackhammer operates on the simple but powerful principles of pressure and impact. By harnessing the force of compressed air or an electric motor, the jackhammer drives a chisel-like bit into hard surfaces with explosive force, breaking them down into manageable pieces. It’s like a mini earthquake in the palm of your hand! So the next time you see a jackhammer in action, don’t just cover your ears and groan – appreciate the engineering marvel at work and marvel at the sheer force of human ingenuity and creativity.

“

FAQs

What is a jackhammer and how does it work?

A jackhammer, also known as a pneumatic hammer or demolition hammer, is a tool that works by using compressed air to power a piston that repeatedly pounds on the surface it is directed at. The percussive force of the hammer breaks up concrete, asphalt, or other hard surfaces into smaller pieces.

How much pressure is required to operate a jackhammer?

Most jackhammers require a minimum pressure of 90 PSI (pounds per square inch) to operate effectively.

How heavy is a typical jackhammer?

A standard jackhammer typically weighs between 20 and 30 pounds, although larger models designed for heavy-duty work can weigh up to 90 pounds.

Are there any safety precautions that need to be taken when using a jackhammer?

Yes, there are several safety measures that should be taken when working with a jackhammer. These include wearing ear and eye protection, using proper lifting techniques, and ensuring that the work area is free from any obstacles.

What types of surfaces can be broken up with a jackhammer?

Jackhammers are primarily used for breaking up concrete, asphalt, pavement, and other hard surfaces. They are often used for demolition work or for creating trenches.

Can a jackhammer be used for digging holes?

While a jackhammer is not designed specifically for digging holes, it can be used to break up soil and other materials in order to create a hole.

How long does a typical jackhammer last?

The lifespan of a jackhammer can vary depending on the brand, model, and amount of use it receives. However, with proper maintenance and care, a jackhammer should last for several years.