How the Drill Press Operates and How to Use It for Precision Drilling: A Complete Guide

If you’re stepping up your DIY game, then it’s time to learn how to use a drill press. This versatile tool is perfect for a wide array of drilling tasks and can make your woodworking or metalworking projects infinitely easier. A drill press gives you accuracy, power, and stability all in one package.

It’s like having a surgical tool for your DIY needs. With proper use and care, a drill press can be a game changer for any DIY enthusiast. So, let’s dive in and learn how to use it!

What is a Drill Press?

If you’re an avid DIY enthusiast, then you know how important it is to have the right tools for your projects. One versatile tool that you should add to your collection is a drill press. So, what is a drill press? It’s essentially a mounted drilling machine that can be used to accurately drill holes through various materials such as wood, metal, and plastic.

The drill press operates on a simple mechanism that transforms circular motion into linear motion using a motor and spindle. The drill bit is attached to the spindle, which moves up and down through a system of gears, allowing for precision drilling. To use the drill press, you’ll need to secure your workpiece to the table, position the bit where you want to drill, and adjust the depth stop according to the desired drilling depth.

Then, turn the machine on and lower the bit slowly until it touches the surface of your material. Keep your hands away from the moving parts and allow the drill to do the work for you. With practice and patience, you’ll be able to create clean and precise holes using your drill press.

Definition and Parts

A drill press is a power tool that is used for drilling holes into different materials like metal, wood, or plastic. It consists of several parts, the most important of which is the drill bit. The drill bit is the part that actually creates the hole by rotating in a circular motion.

Other important parts of a drill press include a table to support the material being drilled, a spindle which holds the drill bit in place, a chuck which tightens the drill bit into the spindle, and a motor which powers the drill press. Drill presses come in a variety of sizes and models to accommodate the needs of different users. They are widely used in industries like woodworking, metalworking, and construction, and are also found in many DIY workshops and garages.

With a drill press, drilling precise and accurate holes is easy and efficient. Whether you are a professional woodworker or just a DIY enthusiast, a drill press is an essential tool to have in your workshop.

Setting Up Your Drill Press

When it comes to working with a drill press, it’s important to understand how the machine operates and how to use it safely and effectively. Firstly, set up the drill press on a sturdy, level surface and make sure the power cord is securely connected. Then, select the appropriate drill bit and adjust the speed settings according to the type of material you’re working with.

Always wear protective gear, including eye and ear protection, and make sure to keep your hands and loose clothing away from the drill bit while it’s in motion. Familiarize yourself with the different features of the drill press, including the depth stop and table height adjustment, to achieve precision and accuracy in your drilling tasks. With practice and attention to safety measures, the drill press can be a valuable asset in any workshop or DIY setting.

Adjusting the Depth and Table Height

When it comes to setting up your drill press, adjusting the depth and table height is crucial in achieving accurate and effective drilling. The depth of the drill refers to how deep the hole will be, and this can be adjusted by simply lowering or raising the drill bit. On the other hand, the table height determines the distance between the drill bit and the workpiece.

This can also be adjusted by moving the table up or down. It’s essential to ensure that the depth and table height are set correctly before drilling to avoid any mistakes or accidents. By doing so, you can achieve the desired depth and angle of the hole precisely.

Overall, adjusting the depth and table height is a fundamental aspect of drill press setup and should never be overlooked.

Inserting and Changing Bits

Setting up your drill press can seem overwhelming if you’re not familiar with the process. But with a few simple steps, you’ll be able to insert and change bits with ease. First, make sure your drill press is turned off and unplugged.

Next, select the drill bit you want to use and insert it into the chuck. Tighten it securely using the chuck key, making sure it’s centered in the chuck. A misaligned bit can cause damage to your drill press and ruin your project.

Finally, adjust the height and depth of the table to accommodate your workpiece. Don’t forget to wear eye protection and hold the workpiece securely while drilling. With these steps, you’ll be able to confidently set up your drill press and tackle any project, big or small.

Using Your Drill Press

If you’re looking to tackle some DIY projects at home, one tool that should be on your list is a drill press. This versatile machine can handle a variety of materials and sizes, making it a great resource for woodworking, metalworking, and more. But before you start drilling away, it’s important to understand how the drill press operates and how to use it properly.

The basic components of a drill press include the base, the column, the head, the table, and the chuck. The base provides stability, while the column holds the motor and the head, which houses the spindle and the chuck. The table can be adjusted up or down and rotated to accommodate various angles.

To operate the drill press, first secure your material to the table, adjust the height and angle as needed, and then select the appropriate speed for your drill bit. Once you’re ready, turn on the drill press and align the bit with your marked drilling location. Use the drill handle to lower the bit into the material, and apply steady pressure to create a clean, precise hole.

By understanding how the drill press works and following best practices for use, you can achieve professional-grade results with ease.

Selecting the Right Speed and Bit

When using your drill press, selecting the right speed and bit is crucial for the success of your project. The speed of your drill press is determined by the material you will be drilling into and the size of the bit you will be using. A slow speed is recommended when drilling metal while faster speeds are suitable for wood.

You should also consider the diameter of the bit as larger bits require slower speeds to prevent overheating and damage to both the bit and material. In addition to speed, selecting the right bit is equally important. The type of bit you choose depends on the material being drilled into and the specific task at hand.

For instance, using a twist drill bit is ideal for drilling smaller holes in wood whereas a spade bit is best for larger holes. It is important to carefully evaluate both these factors before beginning your project as it can drastically impact the outcome.

Drilling the Hole

If you’re a DIY enthusiast, you know that having a drill press can make drilling holes a breeze. But before you start drilling into your material, it’s important to know how to use your drill press correctly. First, ensure that your material is secured tightly in place and adjust the height and angle of your drill bit accordingly.

Once you’re ready, turn your drill press on and slowly lower your drill bit until it makes contact with your material. Use the drill’s handle to apply pressure and drill through the material at a consistent pace. Remember to take breaks and remove the drill bit to clear any debris that may have accumulated in the hole.

With a little practice, your drill press will become a valuable tool in your DIY arsenal.

Removing the Bit and Clean-Up

Removing the Bit and Clean-Up on your drill press can be a messy job, but it’s essential for keeping your tools in tip-top shape. Thankfully, the process is relatively simple and can be done in just a few steps. First, start by unplugging your drill press and removing any debris around the bit with a brush or compressed air.

Next, unscrew the chuck and gently remove the bit using pliers, being careful not to damage the surrounding parts. Once the bit is removed, inspect it for any damage or wear, and clean it with a soft cloth and some lubricant. Finally, reattach the chuck and tighten it firmly back into place, and you’re ready to get back to work! By regularly removing the bit and cleaning your drill press, you’ll not only extend the life of your tool, but also ensure that it performs at its best, every time.

Safety Tips for Using a Drill Press

If you’re new to using a drill press, it’s important to understand how the drill press operates and how to use it safely. The drill press is a powerful tool that can make precise holes in a variety of materials, including wood, metal, and plastic. To begin, it’s important to choose the right drill bit for your project and make sure it is securely fastened into the chuck.

Always wear eye and ear protection and keep loose clothing, jewelry, and long hair away from the drill bit. When operating the drill press, make sure the speed is set correctly for the material and size of the drill bit. Use a clamp or vice to secure the material being drilled and never apply too much pressure or force on the drill bit.

It’s also important to keep the drill press clean and well-maintained to ensure it operates safely and effectively. By following these safety tips, you can use the drill press with confidence and avoid accidents or injuries.

Eye and Ear Protection

When it comes to using a drill press, safety should always be the top priority. Eye and ear protection is a must-have whenever you’re working with power tools. You never know when a flying piece of debris or a loud noise can cause damage.

Make sure you invest in a pair of safety glasses or goggles that are designed to protect your eyes from any sparks or chippings that may come off while working. At the same time, earplugs or earmuffs can help prevent long-term damage to your hearing caused by the loud noise produced by a drill press. By taking these simple steps, you can ensure that your eyes and ears stay safe while you’re busy getting your projects done.

Securing Material and Keeping Hands Clear

When it comes to using a drill press, safety should always be your top priority. One critical aspect of drilling press safety is securing the material you are working on and keeping your hands clear of the drill bit. Before starting your project, make sure the material is tightly clamped down onto the drill press table.

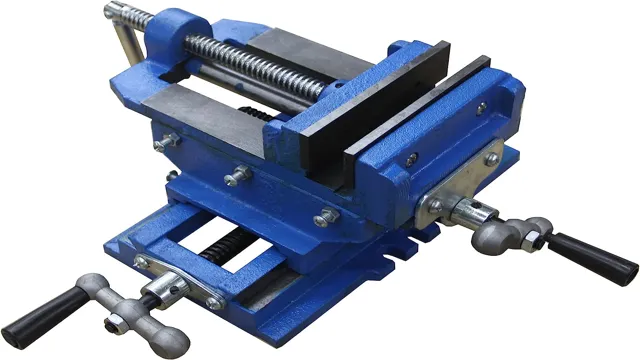

This helps prevent the material from spinning or shifting while you work, which can be dangerous. Additionally, it’s crucial to keep your hands far away from the drill bit while it’s in motion. One way to do this is by using specialized tools, such as a drill press vise, to manipulate the material instead of your hands.

Additionally, always wear appropriate safety gear, like eye protection and gloves, and never wear loose clothing or jewelry that could get caught in the drill. By following these safety tips, you can minimize the risk of accidents and enjoy a successful and injury-free drilling experience.

Conclusion

In conclusion, the drill press is the ultimate blend of power and precision. Its ability to drill holes accurately and efficiently is what makes it a powerful tool in the hands of woodworkers, metalworkers, and DIY enthusiasts alike. But like any other tool, it requires mindfulness, attention, and safety.

Remember to wear proper eye protection, secure the workpiece, adjust the speed and depth, and keep a steady hand. So go ahead and start crafting those beautiful pieces that you have been dreaming of, with the trusty drill press by your side. Happy drilling!”

FAQs

What is a drill press and how does it work?

A drill press is a machine tool used to make holes in various materials. It works by rotating a drill bit which is moved up and down by a spindle, allowing precise drilling.

Can a drill press be used for other tasks besides drilling holes?

Yes, a drill press can also be used for tasks such as sanding, tapping threads, and countersinking.

What safety precautions should be taken when using a drill press?

Always wear eye protection and avoid loose clothing or jewelry that could get caught in the machine. Make sure the machine is securely anchored and the drill bit is sharp and properly installed.

How do you adjust the speed of a drill press?

Most drill presses have a pulley system that allows you to change the speed by adjusting the belt position. Some models also have variable speed controls.

How do you choose the right drill bit for your material?

Consider the material’s hardness and thickness to choose the appropriate drill bit size and material. For example, a diamond-tipped bit may be needed for hard materials like glass or ceramic.

How do you properly align your material for drilling?

Use clamps or a vise to secure your material and ensure it is level with the drill bit. Double-check the depth and angle before starting to drill.

How do you maintain your drill press for optimal performance?

Regularly clean and lubricate the machine, replace worn parts, and ensure the motor is running smoothly. Follow the manufacturer’s guidelines for maintenance and repairs.