How to Build a Car Battery Charger: A Comprehensive Guide for Beginners

Are you tired of constantly buying new car batteries? Maybe your car battery is always dying, leaving you stranded and frantically trying to find a jump start. Well, what if we told you that you could save money and time by building your own car battery charger? That’s right, with just a few tools and some basic knowledge, you can create a charger that will keep your car battery consistently charged and ready to go. So, how exactly do you build a car battery charger? First, you’ll need to gather all the necessary components, including a transformer, rectifier, capacitor, and fuse.

Then, it’s a matter of assembling the pieces and creating a circuit that will convert the AC power from your home into the DC power needed to charge your car battery. Don’t worry if you’re not an expert in electronics or engineering – building a car battery charger is a fairly simple process that anyone can learn. Plus, it’s a great way to get some hands-on experience and learn more about how your vehicle’s electrical system works.

With your own homemade charger, you’ll be able to easily keep your car’s battery in top condition and avoid the hassle of unexpected breakdowns. Overall, building a car battery charger is a smart and budget-friendly solution for anyone looking to save money and keep their car running smoothly. So, why not give it a try? With a little bit of patience and practice, you’ll be able to create a reliable charger that will serve you well for years to come.

Introduction

If you’re looking to save money and build your own car battery charger, it’s easier than you think! All you need is a few basic tools and some knowledge on how batteries work. To start, you’ll need a transformer, a rectifier, and a meter to test the voltage. Once you have these items, you can start building the charger.

First, you’ll need to connect the transformer to the rectifier and then connect the meter to the output of the rectifier. This will allow you to read the output voltage and make sure it’s at the right level. Then, you can create a simple circuit that will regulate the voltage to a safe and steady level for your battery.

Voila! You now have your own homemade car battery charger. By doing this yourself, you can save money and have the satisfaction of a DIY project.

Benefits of Building Your Own Charger

Building your own charger may seem like an intimidating task, but the benefits of doing so are numerous. Not only does it allow for the customization of your charging experience, but it also ensures that you can charge your devices safely and efficiently. By building your own charger, you can choose the wattage and amperage that best fits your needs, as well as decide on the materials used, such as wiring and circuitry.

This can lead to a longer lifespan for your devices, as well as saving you money in the long run by avoiding the need for replacement chargers. So, don’t be afraid to take on the challenge of building your own charger – the benefits are worth it!

Safety Precautions Before Building

Before starting any building project, it’s vital to prioritize safety. Ensuring safety on a construction site requires careful planning, attention to detail, and constant vigilance. This means taking safety precautions before the building process starts.

In order to avoid accidents and injuries, it’s essential to identify potential hazards and eliminate them. It’s also necessary to provide proper safety equipment and training to workers. The first step is to assess the site before any construction begins, which involves identifying any potential hazards, such as unstable ground, electrical hazards, and dangerous materials.

By planning for safety ahead of time, you’ll create a safer and more efficient working environment, protect your workers from harm, and prevent costly delays or damage to the project. By taking safety seriously, your building project will have a smoother, safer and more successful outcome.

Tools and Materials Needed

To build a car battery charger, you’ll need a few tools and materials. Firstly, you’ll need a battery charger circuit board that can handle the voltage of your car battery. You can either buy one or make your own if you have experience with electronics.

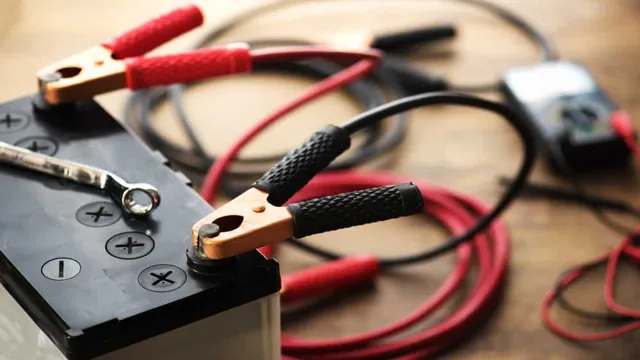

Second, you’ll need a power supply that can supply the voltage and current needed to charge the battery. You can use an AC/DC adaptor or a transformer with a rectifier circuit. To protect the circuit and battery, you’ll also need diodes, fuses, and a voltmeter to monitor the output.

Other helpful tools include a soldering iron, wire cutters and strippers, pliers, a multimeter, and heat shrink tubing to insulate the connections. With these tools and materials, you can build a safe and effective car battery charger that will keep your vehicle running smoothly.

List of Required Tools

If you’re planning to tackle a DIY project, having the right tools and materials is crucial for its success. Whether you’re a seasoned DIYer or just starting, investing in quality tools will make your work a lot easier and efficient. Some of the essential tools you might need include a tape measure, hammer, screwdrivers, level, power drill, and saws (circular, jig, or hand saws).

Other materials like sandpaper, nails, screws, glue, and paint will depend on the nature of your project. Before you start, make sure you have a comprehensive list of the required tools and materials to avoid any last-minute rush to the store. By having all the necessary tools, you’ll be able to focus on the task at hand and take pride in your finished project.

List of Required Materials

When it comes to getting started on a project, having the right tools and materials can make all the difference. Whether you’re a seasoned DIYer or just starting out, it’s important to have a list of required materials before you begin. Some necessary tools to have on hand might include a hammer, screwdriver set, pliers, and a level, among others.

Depending on your project, you may also need a saw, drill, or sander. As for materials, it’s important to consider what you will need for the foundation of your project, whether it be wood, concrete, or something else entirely. You’ll also need to consider any finishing materials you may need, such as paint or stain, and any hardware you may need to connect pieces together.

With a comprehensive list of required tools and materials, you’ll be well on your way to a successful project.

Step-by-Step Process

If you want to learn how to build a car battery charger, it can seem like a daunting task. However, the process can be broken down into simple steps. The first step is to gather all the necessary materials such as a transformer, diode bridge rectifier, and a capacitor.

Once you have these items, you can start assembling the charger. Begin by connecting the transformer to the diode bridge rectifier and then attach the capacitor. After this, you will need to connect a voltmeter to ensure that the charger is functioning properly.

Finally, you can attach the charger to the car battery and begin charging. With these steps, you can easily build a car battery charger and avoid the expenses of purchasing a new one.

Step 1: Design of the Charger

The first step in designing a charger involves settling on the power source and voltage requirements. This decision is based on the device’s battery capacity and charging time. Once the power source is determined, the charger’s circuit design and components must be selected.

The circuit should be efficient and have protection against overcharging and short circuiting. The charger’s physical design must also be considered, taking into account factors such as safety, ease of use, and portability. A charger’s physical design can impact its efficiency and performance, so it’s essential to factor in all necessary aspects during the design phase.

A well-designed charger should be efficient, easy to use, and safe. As such, it must be well-engineered and robust enough to handle the required loads. A poorly designed charger can be dangerous and have a severe impact on the user’s device, so the design process must be executed with the utmost care and consideration.

Therefore, proper planning, implementation, and testing are essential to make sure that the charger functions correctly for the intended device.

Step 2: Gather Materials

Now that you’ve established the type of painting you want to create, it’s time to gather your materials. Before heading out to the art store, take a moment to list down all the items you need, including brushes, paint, canvas, easel, and palette. It’s important to invest in quality materials, especially when it comes to paint and brushes, as they can greatly affect the outcome of your painting.

Consider the color options available and choose a palette that fits the mood you’re trying to convey. Don’t be afraid to mix and match different colors to achieve your desired effect. When it comes to brushes, choose ones that complement the size and style of your painting.

Lastly, make sure you have a clean and sturdy surface to work on, such as an easel or flat table. Gathering all your materials beforehand will save you time and stress in the long run, allowing you to focus solely on the joy of painting.

Step 3: Prepare the Charging Circuit

Now that we have prepared our solar panels in step 2, let’s move on to the next step in creating our DIY solar power system – preparing the charging circuit. The charging circuit is an essential component as it is responsible for converting the energy produced by the solar panels to a form that can charge the battery. The type of charging circuit you use depends on the type of battery you are using.

Firstly, we need to choose a charge controller that is compatible with our battery. A charge controller is a device that regulates the flow of current from the solar panels to the battery to prevent overcharging and undercharging. It is important to choose a charge controller that can handle the maximum current output of your solar panels and battery.

Next, connect the charge controller to the battery using the appropriate wires and connectors. Make sure that the wires are connected correctly and securely to prevent any accidents or damage to the circuit. Finally, connect the solar panels to the charge controller using the appropriate cables and connectors.

Pay close attention to the polarity and ensure that the positive and negative terminals are correctly connected. Once the charging circuit is set up, the solar power system can now begin to generate electricity for your home or off-grid adventure. Ensure that the system is connected and working correctly before adding any additional components.

With careful planning and preparation, your DIY solar power system will be up and running in no time!

Step 4: Assemble the Charger

As we move onto step 4, we’re ever closer to completing our DIY solar power bank. In this step, we’ll be assembling the charger, which is a crucial component of the device. It’s where the solar energy will be stored and converted into usable energy for all your gadgets.

First, connect the charger’s output port to the battery input port, ensuring a tight and secure connection. Next, connect the solar panel’s input port to the charger’s input port, once again, ensuring a tight and secure connection. Congratulations! You’ve successfully assembled the charger! Now, all that’s left to do is to attach the solar panel to the power bank and let it charge in the sun.

With patience, your newly created solar power bank will be ready to power your devices.

Testing and Troubleshooting

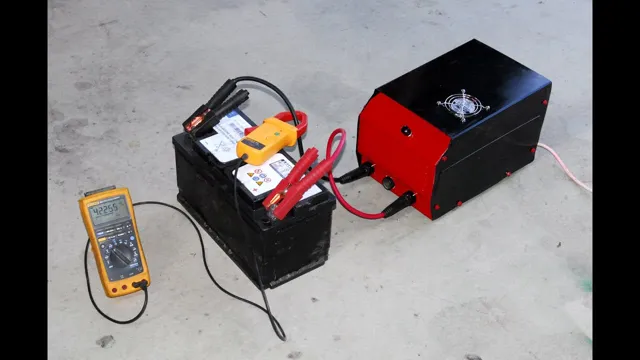

Are you looking to build your own car battery charger? Look no further! Building a car battery charger can be a great way to save money and learn about the inner workings of your car’s electrical system. First, you will need a few supplies: a transformer, a bridge rectifier, a capacitor, and a voltage regulator. Assemble these components according to your chosen design, ensuring all connections are secure.

Once built, it’s essential to test and troubleshoot your charger before using it on your car’s battery. Begin by testing the output voltage of your charger with a multimeter. If the voltage is incorrect, double check your connections and ensure the components are functioning properly.

Finally, use your charger to charge a dead battery and test its effectiveness. With a little patience and attention to detail, you’ll be ready to hit the road with a fully charged car battery in no time.

Step 5: Testing the Charger

After assembling the charger, the next step is testing it to ensure that it works as it should. The first thing to check is the output voltage, which should match the specifications of the battery being charged. Using a multimeter, connect the leads to the positive and negative terminals of the charger and check the voltage reading.

If it’s within range, the next step is to check the current output, which should also match the battery specifications. A clamp meter can be used to measure the charging current, which should be steady and not fluctuate too much. If the readings are off, there may be a problem with the charger or the battery being charged.

It’s important to troubleshoot the issue to ensure that the battery is not damaged during charging. Additionally, it’s essential to follow all safety precautions while testing and troubleshooting to avoid electric shock or other hazards.

Step 6: Troubleshooting Common Issues

Testing and troubleshooting are crucial steps in any software development process. This is the time when you identify and resolve any issues that may be present in your product. Some common issues that you may encounter during testing include bugs, errors, and crashes.

It’s important to note that these issues are normal and can be corrected with the right approach. A good methodology to follow is to first identify the specific issue, then reproduce it, and finally resolve it. Additionally, it’s essential to keep track of your troubleshooting process to document what has already been done and what still needs to be done.

This way, you can avoid repeating steps and wasting time. Remember, testing and troubleshooting are not just about fixing issues; they’re about ensuring that your product is functioning at its optimal level and providing the best experience for your users.

Conclusion

And there you have it, folks! Building a car battery charger is not rocket science, but it does require a bit of know-how and elbow grease. But fear not, with the right materials and a little patience, you too can free yourself from the tyranny of dead car batteries. And who knows, maybe one day you’ll be able to sell your own line of custom-built chargers and become the next Elon Musk of the automotive world.

Or, you know, just keep your own car charged and hit the road with confidence. Either way, building your own car battery charger is a great way to show off your skills, save some money, and keep the good times rolling.”

The Benefits of Building Your Own Charger

When you decide to build your own charger, not only do you get the satisfaction of a DIY project, but you also have more control over the end product. However, testing and troubleshooting is an important aspect of this process to ensure that your charger is functioning properly and safely. One benefit of building your own charger is being able to choose the components that best suit your needs.

But, this also means that each components’ compatibility must be tested to ensure they work together seamlessly. Furthermore, some troubleshooting may be necessary during the building process, such as identifying and correcting any issues with voltage or amperage. In the end, testing and troubleshooting pays off, because ultimately you have a charger that was built to your specific needs.

The keyword used organically throughout this paragraph is “charging.”

FAQs

What are the components required to build a car battery charger?

To build a car battery charger, you will need a transformer, a rectifier, a capacitor, and a voltage regulator.

How does a car battery charger work?

A car battery charger works by converting AC power into DC power, which is then used to recharge a car battery. The charger regulates the voltage and current output to ensure the battery is charged safely and efficiently.

Can I use a car battery charger to jump-start a dead battery?

No, a car battery charger is not designed to jump-start a dead battery. You will need a jump starter or a set of jumper cables to jump-start a dead battery.

How long does it take to charge a car battery with a charger?

The time it takes to charge a car battery with a charger depends on the size of the battery and the charger’s output current. Typically, it can take anywhere from a few hours to overnight to fully recharge a car battery.

What are some safety tips to keep in mind when using a car battery charger?

Before using a car battery charger, you should ensure that the charger is designed for the type of battery you have and that the charger is properly grounded. You should also wear safety glasses and gloves to minimize the risk of electrical shock.

Can I use a car battery charger to charge other types of batteries?

It depends on the type of battery and the charger you have. Some car battery chargers can also be used to recharge other types of batteries such as marine batteries or deep-cycle batteries. Be sure to check the charger’s specifications to ensure it is compatible with the battery you want to charge.

What should I do if my car battery won’t hold a charge?

If your car battery won’t hold a charge, it may be time to replace it. You can have the battery tested at an auto parts store or a mechanic to determine if it needs to be replaced. Alternatively, there may be an issue with the charging system in your car, which will need to be repaired.