Are you tired of your workpiece slipping while drilling holes? Or do you want to ensure precision in your drilling project? Then, clamping your table drill press is the ultimate solution you need.

Although clamping a table drill press sounds like a simple task, it’s crucial to do it correctly to avoid damaging your workpiece or drill bit. In this blog post, we’ll take you through a step-by-step guide on how to clamp a table drill press successfully.

From preparing your workstation to tightening the clamps securely, we’ll cover all the essential aspects you need to consider. Whether you’re a beginner or an experienced woodworker, our guide will provide you with the necessary knowledge and skills to clamp your drill press with ease. So, sit tight and read on.

You’ll discover some practical tips and tricks that will make your drilling projects more enjoyable and less stressful. By the end of this guide, you’ll have the confidence to clamp your table drill press correctly and efficiently.

Introduction

Clamping a table drill press is an essential skill for anyone who wants to make precise and accurate drill holes. The process may seem daunting, but it’s actually quite straightforward. First, make sure that the table is clean and clear of any debris.

Then, select the appropriate clamp for your drill press. There are a variety of clamps available, including C-clamps, quick-release clamps, and spring clamps. Once you have your clamp, place it over the drill press table and tighten it securely.

Make sure to position the clamp so that it provides enough stability and support for your workpiece. Once your clamp is in place, you’re ready to start drilling. With a properly clamped table drill press, you can be confident that your holes will be accurate and precise, every time.

What is Clamping?

Clamping is a process of securing two or more objects together to prevent movement or separation. It involves the use of a tool called a clamp, which applies pressure to hold two pieces of material together. Clamping is used in a variety of applications, including woodworking, metalworking, and welding.

In woodworking, clamping is used to hold pieces of wood together while glue dries. In metalworking, clamps are used to hold sheet metal in place while it is bent or cut. Clamping is also an important part of welding, as it allows the welder to hold two pieces of metal together while they are being fused.

Overall, clamping is a simple yet essential process that is used in countless industries to ensure accuracy and stability.

Why is Clamping Important?

Clamping is a vital aspect of many industries, including manufacturing, construction, and automotive. In its most basic form, clamping involves securing two objects together through pressure, preventing them from moving or separating.

But why is clamping important? Well, it ensures the accuracy and precision of a finished product and improves overall safety. Without proper clamping, production processes can be compromised, leading to faulty products, wasted resources, and even dangerous situations.

So, whether you’re constructing a building or assembling an engine, clamping plays a crucial role in ensuring the quality and durability of the final product.

Clamping the Table Drill Press

If you’re using a table drill press, it’s important to know how to properly clamp it in place. This will not only ensure precision in your drilling, but safety as well. First, make sure your workpiece is securely in place on the table.

Then, adjust the height of the drill bit to the appropriate level. Next, locate the clamping mechanism on your press. This may be a set of screws or levers that tighten down onto the table.

Depending on your press, you may need to use a wrench or other tool to tighten the clamps. Once you’ve secured the press in place, double-check that your workpiece is still secure before beginning drilling. Clamping your table drill press may take a bit of practice, but it’s an important step to ensure safe and accurate drilling.

Step 1: Choose the Right Clamps

When it comes to clamping down your workpieces on a table drill press, choosing the right clamps is crucial. The last thing you want is to have your material slip or move during the drilling process, which can damage your workpiece or even cause injury. There are a few different types of clamps you can choose from, including toggle clamps, cam clamps, and screw clamps.

Each of these clamps has its own advantages and disadvantages, so it’s important to consider the specific needs of your project. For example, if you need to hold down a curved or irregularly shaped workpiece, a cam clamp might be your best bet. On the other hand, if you’re working with a flat and smooth material, a screw clamp might be more appropriate.

Whatever clamp you choose, make sure it’s securely fastened to the table and that your workpiece is held tightly in place before you start drilling. With the right clamps, you can ensure accurate and safe drilling every time.

Step 2: Position the Clamps

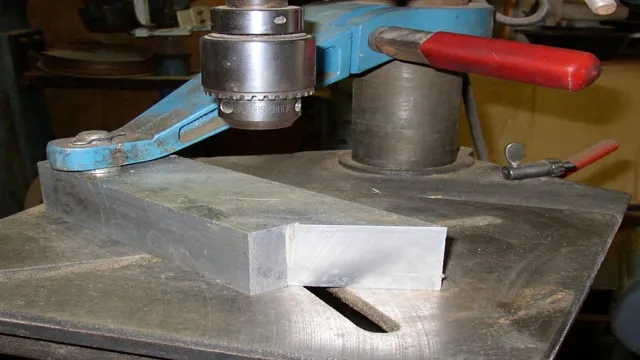

When using a table drill press, it is essential to properly clamp it down to ensure accuracy and safety. To do so, first, ensure the surface underneath the drill press is clean, flat and even. Next, position the clamps on opposite sides of the drill press to secure it in place.

Make sure the clamps are positioned in a way that won’t interfere with the drilling process and will provide a stable foundation for the drill press to work on. It’s essential to check and double-check that the clamps are securely fastened and won’t loosen during the drilling process. By taking these steps, you can ensure that the drill press stays in place while you work, making it safer and easier to use.

Proper clamping is critical for accurate and safe drilling, and it helps to prevent accidents and damage to your workpiece. So always take the time to clamp your table drill press carefully and correctly to ensure the best results.

Step 3: Tighten the Clamps

After adjusting the necessary settings on your table drill press, the next step is to tighten the clamps to secure the workpiece in place. This will prevent any movement or wobbling during drilling, ensuring accurate results. It’s important to use the appropriate clamps for your particular table drill press model to ensure a tight fit.

Tightening the clamps too much can damage the workpiece, while not tightening enough can result in it slipping during drilling. It’s always a good practice to double-check the tightness of the clamps before beginning any drilling project. By taking the time to properly clamp your workpiece, you can avoid frustrating mistakes and achieve professional-level drilling results.

Other Factors to Consider

When it comes to clamping a table drill press, there are a few other factors you should consider to ensure that you get the most out of your tool. First off, you’ll need to consider the size and type of material you’ll be working with. Larger pieces may require heavier-duty clamps to keep them in place.

You’ll also want to make sure that you use a level surface to ensure accuracy in your drilling. Additionally, consider the type of drill bit you’ll be using – smaller bits may require more delicate clamping methods to avoid damaging your workpiece. Keep in mind that proper clamping is crucial for safe and efficient drilling, so take the time to choose the right clamps for your project and always double-check that they’re securely fastened before you begin.

With the right technique and tools, you’ll be able to clamp your table drill press quickly and easily for precise and safe work every time.

Safety Precautions

When it comes to ensuring safety on the job, there are several factors to consider beyond just following basic safety protocols. For example, it’s important to take into account the environment in which you’ll be working. Is the area well-lit? Is there potential for exposure to harmful chemicals or other hazards? Additionally, you should always be aware of your own physical limitations and take precautions accordingly.

Are you wearing appropriate footwear with good traction and support? Are you taking enough breaks and staying hydrated to avoid fatigue-related accidents? By thinking through these other factors, you can put yourself and your colleagues in the best possible position to stay safe and healthy while on the job.

Repeated Use and Maintenance

When it comes to purchasing equipment or machinery, we often focus on the initial cost and overlook the importance of maintenance and repeated use. In reality, regular maintenance can save us from costly repairs and replacements in the long run while also extending the lifespan of the equipment. Other factors to consider include the availability and cost of spare parts and the frequency of use.

If the equipment is rarely used, investing in regular maintenance may not be necessary, but for frequently used machinery, regular check-ups and upkeep are crucial to keep it functioning properly. Although it may seem like an added expense, investing in maintenance can actually save you time and money in the long run. In the end, it’s essential to consider all of these factors before making any purchase to ensure that you are getting your money’s worth.

Conclusion

In conclusion, clamping a table drill press is like learning to tie your shoes – it’s a simple task that can be easily taken for granted. But just like tying your shoes, if you don’t do it properly, things can get messy. So take your time, use the right tools, and make sure everything is secure before you start drilling.

Because when it comes to power tools, a little bit of caution goes a long way. Now go forth and clamp with confidence!”

FAQs

What is a clamp for a table drill press?

A clamp is a tool used to secure and hold an object in place, in this case, a table drill press.

Why do I need to clamp the table drill press?

Clamping the table drill press ensures that the workpiece stays in place, preventing it from moving or slipping during drilling, leading to a more accurate and precise hole.

How do I choose the right clamp for my table drill press?

To choose the right clamp for your table drill press, consider the size of the drill press table, the size and shape of the workpiece, and the clamping force needed. You can choose from various types of clamps, such as C-clamps, F-clamps, and toggle clamps.

Can I use any type of clamp on my table drill press?

No, not all types of clamps can be used with a table drill press. It would be best to use clamps designed explicitly for drill presses to ensure compatibility, safety, and accuracy.

How do I properly clamp the workpiece on my table drill press?

To clamp the workpiece on your table drill press, position it on the drill press table, align it with the drill bit, and secure it in place using the clamp. Adjust the clamping force as needed, making sure the workpiece is stable and secure before drilling.

What precautions should I take when clamping on my table drill press?

When clamping on a table drill press, make sure to tighten the clamp securely, but not so tight that it damages the workpiece or the drill press table. Also, avoid positioning the clamps in areas where they may get in the way of the drilling process.

Can I drill without using a clamp on my table drill press?

It is not recommended to drill without using a clamp on a table drill press as it may cause the workpiece to shift or move during drilling, leading to an inaccurate and unsafe hole.