How to Clamp Small Boards on a Drill Press: A Step-by-Step Guide

If you’re like many DIY enthusiasts, you know that drilling small pieces of wood can be quite challenging. It’s not easy to hold those tiny pieces securely enough to make a clean, straight hole. If you’re struggling with this, you’re not alone.

Clamping small boards on a drill press is a common issue many people face. But don’t worry! We’re here to help. In this blog post, we’ll show you some tips and tricks for securing your little workpieces on a drill press.

With just a few simple steps, you’ll be able to drill perfect holes in your small boards without any trouble. So, whether you’re working on a DIY project, a home renovation, or any other woodwork task that requires dealing with small boards, this post is for you. Keep reading to discover how to clamp your small boards on a drill press like a pro.

Understanding Small Board Clamping

Clamping small boards can be a tricky task, especially when using a drill press. The key is to choose the right type of clamp and position it correctly. For small boards, a C-clamp or spring clamp can be used effectively.

The clamp should be positioned perpendicular to the board and close to the drilling area for maximum support. It’s important to ensure that the clamp is tight enough to prevent the board from shifting but not too tight that it damages the wood. Additionally, using a sacrificial board underneath the small board can help prevent tear-out while drilling.

By following these tips and taking the time to properly clamp your small boards, you can achieve precise drilling results.

Problems with Small Boards on a Drill Press

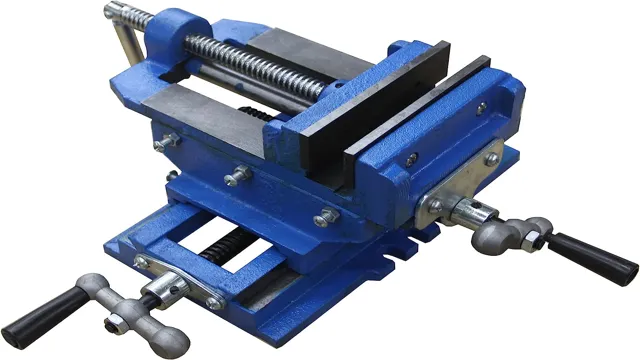

When it comes to drilling small boards on a drill press, it can be challenging to ensure a secure grip without damaging the surface. The key to success lies in understanding small board clamping techniques. One common method is to use a drill press vise, which can grip the board tightly and provides stability during the drilling process.

Another option is to use a clamp or two, placing them on either side of the drill bit to hold the board in place. It’s important to position the clamps far enough away from the drilling area to avoid interference, and to use a sacrificial backing board to protect the surface from damage. With careful consideration and practice, even the smallest boards can be drilled safely and effectively on a drill press.

Types of Clamps for Small Boards

When it comes to woodworking, small board clamping can be a real challenge. It can be hard to find the right tool for the job, but understanding the different types of clamps that are available can make things easier. One option for small board clamping is the quick-release bar clamp.

These clamps have a simple design and are easy to use. Another option is the spring clamp, which is great for holding small pieces in place while you work on them. And for those awkward angles, the corner clamp is a must-have.

It allows you to clamp two boards together at a perfect right angle, making it easier to join them together. Regardless of which type of clamp you choose, make sure to test it out on scrap pieces before using it on your finished product to avoid any unwanted damage.

Tips for Clamping Small Boards on a Drill Press

If you’ve ever tried to drill through a small board on a drill press, you know how difficult it can be to keep the board secure and in place. Thankfully, there are a few tips and tricks you can use to clamp small boards on your drill press. One option is to use a vise grip or clamp to secure the board to the table of the drill press.

Another trick is to attach a small block of wood to the board using adhesive, and then clamp the block of wood to the table of the drill press instead. This method allows you to drill through the board without worrying about it slipping out of place. You can also try using a jig to hold the board in place, or even fashion your own custom clamp using a few simple materials.

With a little creativity and experimentation, you’ll be able to find the perfect method for clamping small boards on your drill press.

Using a Vise Clamp for Small Boards

Clamping small boards on a drill press can be a challenge, especially if you don’t have the right equipment. One tool that can help is a vise clamp. These clamps are designed to hold small objects securely in place, making them ideal for use with drill presses.

To use a vise clamp, simply attach it to the drill press table and position your board in the jaws of the clamp. Tighten the jaws until the board is held firmly in place, then adjust the angle and height of the drill bit as needed. With a vise clamp, you can ensure that your small boards stay in place while you drill, reducing the risk of errors and increasing your accuracy.

So if you’re struggling to clamp small boards on your drill press, try using a vise clamp and see the difference it can make.

Using a C-Clamp for Small Boards

If you’re an avid crafter or DIY enthusiast, the chances are that you’ve come across the need to clamp small boards onto a drill press. While many clamps can get the job done, a C-clamp is an excellent option for smaller boards. Not only are they easy to use, but they’re also relatively cheap compared to other clamps.

The beauty of using a C-clamp is that it creates a secure hold on the board without damaging the surface. All you need to do is choose the right size and fit it onto the drill press. One handy tip is to place a small piece of wood or shim on the opposite side to prevent the clamp from leaving an indentation on the board.

Now you can enjoy a safe and straightforward clamping process that will allow you to focus on your drilling project. So, if you need to clamp small boards on your drill press, consider using a C-clamp.

Using a Quick Release Clamp for Small Boards

Quick Release Clamp for Small Boards When it comes to using a drill press, clamping small boards can be a bit of a challenge. Fortunately, using a quick release clamp can make the task much easier. Simply attach the clamp to the work surface, adjust the jaws to fit the size of your board, and tighten the clamp.

This will secure your board in place, allowing you to make accurate and precise cuts. One advantage of using a quick release clamp is that it can be adjusted with just one hand, which makes it very convenient to use. Additionally, these clamps are available in various sizes, so you can find one that’s perfect for your needs.

Overall, a quick release clamp for small boards is a great tool to have in your arsenal, especially when using a drill press.

Safety Measures for Clamping Small Boards on a Drill Press

Clamping small boards on a drill press can be a bit tricky, but it’s essential to ensure your safety while working. First things first, make sure your drill press is properly secured to a sturdy surface before beginning any work. Next, choose the appropriate clamp for your board size and shape.

A standard clamp may not work for small or irregularly shaped pieces, so consider using a specialized clamp or even making your own custom clamp. It’s important to position the clamp securely so as to prevent the board from slipping or turning while drilling. Keep in mind that using too much pressure can crack or damage the board, so apply moderate pressure only.

It’s also a good idea to use protective gear such as gloves and safety glasses to avoid any injuries. By following these safety measures, you’ll be able to effectively clamp small boards on a drill press and complete your project safely.

Wearing Personal Protective Equipment

When it comes to using a drill press to clamp small boards, safety should always be a top priority. One essential safety measure to keep in mind is wearing personal protective equipment (PPE). This includes safety glasses or goggles to protect your eyes from flying debris, a dust mask or respirator to prevent inhalation of wood dust, and hearing protection to guard against the loud noise of the drill press.

PPE can seem uncomfortable or cumbersome, but it’s important to remember that they help ensure your safety while operating heavy machinery. Just like how a football player wouldn’t take the field without a helmet, you shouldn’t operate a drill press without the proper PPE. By taking these precautions, you’ll be able to focus on the task at hand and not worry about potential safety hazards.

Securing the Board Firmly

Securing a small board firmly on a drill press may seem like a simple task, but it’s important to take the necessary safety measures to avoid accidents. One of the best ways to do this is by using a clamp or vice to hold the board securely in place. A clamp can be attached to the drill press table, and the board can be held down with a pair of adjustable jaws.

It’s also important to make sure the board is positioned correctly before drilling, as any misalignment can cause the bit to bind and potentially snap. Additionally, protective equipment like safety glasses and gloves should be worn at all times. By taking these precautions, you can ensure that your drilling experience is not only accurate but also safe.

Conclusion

In the world of woodworking, clamping small boards on a drill press can be a daunting task. But fear not, my friends! With a bit of ingenuity and some gadgetry, you’ll be able to secure those tiny pieces with ease. Whether you opt for a specialty clamp or a DIY solution, the key is to keep safety in mind and give yourself plenty of room to work.

So go forth, my fellow craftsmen, and let the drilling begin!”

FAQs

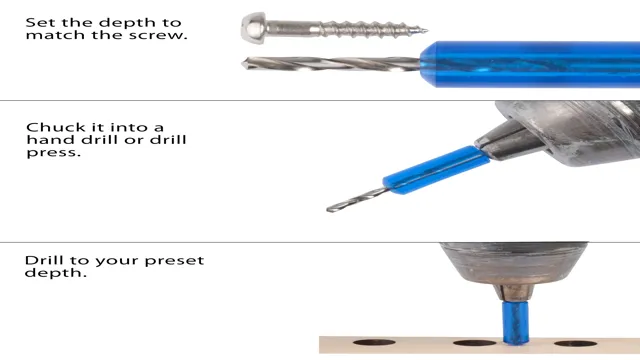

What is a drill press clamp and how does it work?

A drill press clamp is a device used to hold small boards securely in place while drilling. It works by tightening the clamp around the board, which prevents it from sliding or moving during the drilling process.

What are the benefits of using a drill press clamp?

Using a drill press clamp can help to ensure greater accuracy and precision when drilling small boards. It also helps to reduce the risk of injury by keeping the board securely in place during the drilling process.

How do you choose the right size and type of drill press clamp for a small board?

When choosing a drill press clamp for a small board, it is important to consider the thickness of the board as well as the size and shape of the clamping surface. Look for clamps that are specifically designed for small boards and that can be adjusted to fit a range of dimensions.

Can you use a regular clamp for small boards on a drill press?

While it is possible to use a regular clamp for small boards on a drill press, it is not recommended. Regular clamps may not be designed to hold the board securely in place during the drilling process, which could lead to inaccurate or incomplete holes.

What are some tips for using a drill press clamp on small boards?

To get the best results when using a drill press clamp on small boards, be sure to choose the right size and type of clamp, adjust the clamping surface to fit the board securely, and tighten the clamp firmly before starting the drilling process. It is also a good idea to double-check the positioning of the board before drilling to ensure accuracy and precision.

Can a drill press clamp be used for other types of materials besides wood?

Yes, a drill press clamp can be used for other types of materials besides wood, such as metal, plastic, or even ceramics. However, it is important to choose a clamp that is specifically designed for the material you will be drilling to ensure the best results.

Are there any safety precautions that should be taken when using a drill press clamp on small boards?

Yes, it is important to wear protective eyewear when using a drill press clamp on small boards, as well as to keep your hands and fingers away from the drilling area. Additionally, be sure to fully tighten the clamp before beginning the drilling process to prevent the board from slipping or moving.