How to Hollow Grind a Knife with a Bench Grinder: Tips and Techniques for Perfect Results

Hollow grinding is a technique that many professional knife makers utilize to give their blades a distinct convex shape and sharpness. It takes precision and skill to achieve, but with the right tools and knowledge, anyone can learn how to hollow grind a knife with a bench grinder. A bench grinder is a highly efficient and versatile machine that can sharpen, shape, and polish metal with ease.

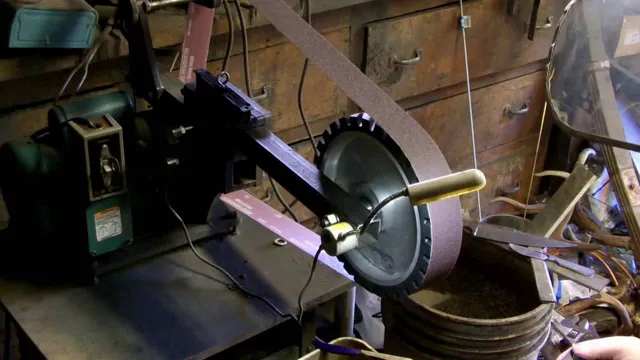

When used correctly, it can work wonders on dull or damaged knives by removing material from the blade’s edge, creating a concave shape that tapers to a thin, sharp edge. But, how do you go about hollow grinding a knife with a bench grinder? The process involves setting up the grinder with the correct grinding wheel and adjusting the tool rest to the proper angle. You’ll also need to make a jig to hold your knife securely and help guide it over the grinding wheel.

Once you’re set up correctly, it’s a matter of finesse, patience, and paying attention to the details. In this post, we’ll explore in detail the steps required to hollow grind a knife with a bench grinder, covering everything from the essential tools and materials you’ll need to the techniques you’ll use to achieve the desired result. Whether you’re a professional knife maker or someone who wants to sharpen and shape their knives at home, with our guide, you’ll learn how to use a bench grinder to create a razor-sharp blade that’s ready for any task.

What is Hollow Grinding?

Hollow grinding is a technique used for sharpening knives that creates a concave, or hollow, edge on the blade. To achieve this effect, you’ll need a bench grinder with a specialized grinding wheel designed for hollow grinding. First, adjust the grinder’s rest to match the angle of the bevel on the knife blade.

Next, use the grinder to remove material from the edge of the blade in short, controlled passes. The process of hollow grinding removes more material from the blade than traditional sharpening methods, resulting in a thinner, sharper edge. One of the benefits of hollow grinding is that it can be used on a variety of blade types, from knives to scissors to chisels.

With practice, you can achieve a razor-sharp edge that will make your cutting tasks a breeze. So if you’re looking to take your knife sharpening to the next level, consider learning how to hollow grind with a bench grinder.

Definition of Hollow Grinding

Hollow grinding is a term used in the world of knife making and woodworking, and it refers to the process of grinding a concave bevel edge down the length of a blade or cutting tool. This technique creates a thinner, more flexible blade that is ideal for slicing or carving. The process involves the use of a specialized grinding wheel that is shaped to create the desired hollow grind.

The blade is then held at the appropriate angle against the wheel, with the edge of the blade being ground down to the desired depth. The resulting edge is sharp and durable, making it ideal for a variety of cutting tasks. Whether it’s for professional use or DIY projects, hollow grinding is an essential technique for anyone who wants to create sharp, high-quality tools.

With the right tools and expertise, even beginners can achieve impressive results using this method.

Why Use a Bench Grinder for Hollow Grinding?

If you are wondering how to hollow grind a knife with a bench grinder, you’ve come to the right place. Hollow grinding is the process of creating a concave surface on the blade, which gives it a sharper edge and more stability while cutting. While there are different tools available for hollow grinding, a bench grinder is one of the best options out there.

Bench grinders come with specialized grinding wheels that can create an accurate and consistent hollow grind on your knife blades. They are also versatile and adjustable, which means you can customize the depth of your grind. Additionally, bench grinders are easy to use and come with safety features that protect you from injury.

So, if you want to get the sharpest and most precise results when hollow grinding your knives, a bench grinder is definitely the way to go.

Advantages of Using a Bench Grinder

A bench grinder is a versatile tool that can be used for various tasks, but hollow grinding is one of its strong suits. Using a bench grinder for hollow grinding offers many advantages, such as precision, speed, and the ability to create sharp and smooth edges. Bench grinders come with adjustable and removable guards to help ensure safety during use, making them an ideal option for both novice and experienced users.

Additionally, bench grinders are cost-effective and easy to maintain, making them a practical investment for anyone who regularly works with tools that require frequent sharpening. So, if you want to achieve razor-sharp edges and reduce your sharpening time, using a bench grinder for hollow grinding is a great option to consider.

Things You Will Need

If you’re looking to take your knifemaking skills to the next level, knowing how to hollow grind a blade is a must. Hollow grinding is a technique that involves removing metal from the blade’s underside to create a concave, or “hollow,” surface. This not only makes the blade sharper but also lighter and more flexible, making it easier to handle.

To start, you’ll need a bench grinder with a fine-grit wheel, as well as safety goggles, a dust mask, and a pair of gloves to protect your hands. You’ll also need a marker to draw the desired shape onto the blade and a jig to hold the blade at the proper angle during grinding. Once you have everything you need, start by marking the blade’s shape onto the metal.

Then, attach the blade to the jig and slowly move it back and forth over the grinder wheel, taking care not to overheat the blade or grind away too much material. It may take some practice to get the hang of it, but with a little patience and perseverance, you’ll soon be able to hollow grind a knife like a pro!

List of Required Tools and Materials

To complete your DIY project successfully, there are certain tools and materials you’ll need to have on hand. Here’s a comprehensive list of the things you’ll need for a successful project. First, a quality measuring tape will be important in ensuring accurate measurements throughout the project.

Hammers, screwdrivers, and other basic hand tools will also be essential. Additionally, you may need power tools like drills and saws to help you complete the project efficiently. Make sure you invest in good quality equipment that can withstand heavy use.

Other essential materials to consider include various screws, nails, and bolts, as well as adhesives like wood glue. Finally, you’ll need appropriate safety gear like goggles, gloves, and ear protection to ensure you stay safe while you work. By having all of these tools and materials on hand before you begin your project, you’ll set yourself up for success and make the process much smoother.

Step-by-Step Guide to Hollow Grind Your Knife with a Bench Grinder

If you’re looking to perfect your knife skills, then you might want to learn how to hollow grind your knife using a bench grinder. The process might seem intimidating, but with some patience and practice, you can achieve a razor-sharp edge that’s great for slicing and dicing. The first step is to set up your bench grinder with the correct wheels and attachments.

Next, you’ll need to adjust the angle and height of the tool rest to match the blade’s curvature. Once that’s done, you’re ready to start grinding away at the blade using an even, controlled stroke. Don’t forget to frequently check and adjust the angle as you go to ensure a consistent, symmetrical grind.

When you’re satisfied with the shape of the grind, switch to finer grit sanding belts to smooth out any rough spots and refine the edge even further. With a bit of practice and perseverance, you’ll be able to achieve that perfect hollow grind that every knife enthusiast strives for.

Step 1: Prepare your Tools and Materials

Hollow Grinding a Knife. Hollow grinding a knife is an essential skill for any knife maker or DIY enthusiast who wants to enhance their project’s aesthetics while improving the blade’s functionality. To get started, you need to prepare your tools and materials.

You will need a bench grinder with a variable speed control, a knife jig, a sharpening stone or sandpaper, safety goggles, and a dust mask. These tools and materials will play a critical role in ensuring your safety throughout the grinding process and delivering a sharp blade that will serve you well. Once you have all the necessary items, you can proceed to the next step of your hollow grinding project.

Remember to put on your safety goggles and dust mask during the grinding process to protect your eyes and lungs from flying debris and dust. With the right tools and safety gear in place, you’ll be well on your way to mastering the art of hollow grinding.

Step 2: Adjust the Grinding Wheels

Adjusting the grinding wheels is a crucial step when it comes to hollow grinding your knife with a bench grinder. The first thing you need to do is to make sure the grinding wheel is properly aligned with the knife blade. This will ensure that the bevel angle is consistent across the entire edge of the blade.

Start by adjusting the tool rest and bringing it closer to the grinding wheel. This will give you more control over the amount of material that is being removed. It’s important to keep the tool rest level and parallel to the grinding wheel to avoid any uneven grinding.

You can then adjust the angle of the grinding wheel to match the bevel angle you want on your knife. It’s recommended to start with a larger angle and work your way down until you reach the desired angle. This will help you avoid grinding away too much material from the blade.

Once you’ve successfully adjusted the grinding wheels, you’re ready to begin hollow grinding your knife.

Step 3: Position the Knife Blade

Now that your knife is securely clamped to the work surface, it’s time to position the blade of the knife. This step is crucial because if the blade is not positioned correctly, you won’t achieve the desired hollow grind. To position the blade, switch on the bench grinder and bring the rotating wheel to a standstill.

Make sure the wheel is turned off before doing this. Then, position the blade of the knife parallel to the top of the wheel but slightly above it. Be sure not to apply too much pressure or force the blade too far down.

You need to create enough space between the blade and the wheel to allow for smooth gliding of the blade over the wheel. Once positioned, you can switch on the grinder and slowly begin to move the blade over the wheel, maintaining the same angle and applying gentle pressure. You’ll hear and feel the grinding process take place – this is perfectly normal.

Just don’t forget to take breaks and cool the blade down by dipping it in water periodically. Follow these steps, and you’ll be well on your way to creating a perfectly hollow ground knife that will make all your cutting tasks a breeze.

Step 4: Start Grinding

Now that you have your work plates and angle grinder set up, it’s time to start grinding your knife. The most important thing to keep in mind when grinding is to maintain a consistent angle throughout the process. This will ensure that your knife has a uniform hollow grind.

Start with the coarsest grit belt first, and work your way up to a finer grit. Take your time and make sure you are pressing the blade firmly against the work plate. If you feel the blade getting too hot, dunk it in a bucket of water to cool it down.

Remember that grinding a knife takes some time and patience, but the end result will be well worth it. With practice, you’ll be able to achieve a perfect hollow grind every time. So let’s get to grinding and achieve that razor sharp edge on your knife!

Step 5: Do the Same on the Other Side

After you’ve hollow ground one side of your knife, it’s time to do the same on the other side. It’s important to maintain the same angle as the first side to ensure consistency in the grind. Begin by setting the tool rest to the same angle as before, and then turn on the bench grinder.

As with the first side, start at the tip of the blade and slowly move it towards the handle, using the same amount of pressure as before. Remember to keep the blade cool by periodically dipping it in water. Once you’ve completed the other side, check for any inconsistencies in the grind and make any necessary adjustments.

A perfectly hollow ground knife will have a sharp and even edge, perfect for slicing through any material with ease.

Step 6: Check for Consistency and Sharpness

When it comes to achieving a perfectly hollow-ground knife, consistency and sharpness are essential. After completing the previous steps, it’s time to check for these crucial qualities. Start by examining the blade’s edge under a bright light to ensure the grind is straight and evenly shaped.

Any inconsistencies in the width or angle of the grind will affect the knife’s sharpness and durability. Once you’re confident in the consistency of the grind, it’s time to test the blade’s sharpness by making a few cuts into a soft material like paper or cardboard. If the blade slices through the material effortlessly, it’s sharp and ready to use.

However, if it struggles or tears the material, it may need further honing or sharpening. Focus on achieving a consistent and sharp edge, and you’ll have a hollow-ground knife that performs exceptionally well.

Tips and Tricks for Better Results

If you’re looking to sharpen your knife at home, you may be wondering how to hollow grind a knife with a bench grinder. To start, it’s important to have the right equipment. You’ll need a bench grinder, a jig or guide for holding the blade at the correct angle, and a coarse grit grinding wheel.

Once you have your equipment set up, it’s time to begin the grinding process. Hold the blade securely in the guide, ensuring it is at the correct angle for the grind. Then, slowly move the blade across the grinding wheel, keeping a consistent angle and pressure throughout.

As you grind, periodically dip the blade in water to prevent overheating and to ensure a smoother grind. It may take some practice to get the hang of it, but with time and patience, you can achieve a razor-sharp, hollow-ground edge on your knife. Remember to always be mindful of safety while working with power tools.

Do’s and Don’ts of Hollow Grinding

Hollow grinding can be a challenging technique to perfect, but with the right tips and tricks, you can produce excellent results. One crucial consideration when hollow grinding is the angle of the blade. It’s essential to ensure that you maintain a consistent angle throughout the process, or you risk creating an uneven grind on the blade.

Additionally, make sure that you’re using a quality grinding wheel and that it’s positioned correctly. Use a light touch when applying pressure to the blade, as excessive pressure can cause heat buildup, resulting in poor grinding. Don’t forget to clean your equipment regularly to ensure it’s working at its best.

Finally, always prioritize safety when using any power tools, wearing protective gear and following safety protocols. With these do’s and don’ts in mind, you can hone your hollow grinding skills and produce top-quality blades for your projects.

Conclusion

In conclusion, mastering the art of hollow grinding a knife with a bench grinder is a true test of patience, precision and skill. With the right technique and tools, you can achieve sharp edges that will slice through anything like a hot knife through butter. So, sharpen your focus, keep your grind steady and before you know it, you’ll be cutting through vegetables like a pro chef.

Remember, a dull knife is a dangerous one, so keep your edges sharp and stay sharp yourself!”

FAQs

What is a hollow grind?

A hollow grind is a type of knife edge that is concave, with a thin, sharp edge.

What are the benefits of a hollow grind?

A hollow grind allows the knife to have a very thin, sharp edge that is excellent for slicing and cutting tasks. It also provides the knife with a lightweight and balanced design.

What type of bench grinder should I use for hollow grinding?

A bench grinder with a variable speed control is recommended for hollow grinding, as this allows you to adjust the speed to suit your needs and the type of metal you are grinding.

What type of grinding wheel is best for hollow grinding a knife?

A soft, fine-grit grinding wheel is ideal for hollow grinding a knife, as it will not remove too much material at once and will leave a smooth, polished edge.

How do I set the angle for a hollow grind on a bench grinder?

To set the angle for a hollow grind, you will need to adjust the tool rest on your bench grinder. Start by setting the tool rest to a 45-degree angle and adjust as needed for your specific knife and grinding needs.

How do I maintain a hollow grind on my knife?

To maintain a hollow grind on your knife, you will need to frequently sharpen and hone the blade to keep the edge sharp. You should also avoid using the knife for heavy-duty tasks that could cause the edge to become damaged.

Can I hollow grind a knife without a bench grinder?

While a bench grinder is the easiest way to achieve a hollow grind, it is possible to achieve a similar effect using other tools, such as a belt sander or sharpening stones. However, it may require more time and effort to achieve the desired results.