How to Make a Wood Marking Gauge: A Step-by-Step Guide for DIY Enthusiasts

Are you looking to add a touch of handmade to your woodworking projects? One way to achieve that is by making your own marking gauge from wood. A marking gauge is a simple yet versatile tool used in woodworking to mark straight parallel lines accurately. Unlike other marking tools such as pencils or rulers, a marking gauge allows you to control the depth of your markings, ensuring consistency and precision.

In this blog post, we’ll discuss step-by-step how to make a wood marking gauge, the tools needed, and some tips to help you get the most out of your new tool. Whether you are a beginner or a seasoned woodworker, making a marking gauge is a fun and easy project that will add value to your woodworking toolkit. So, let’s get started!

Materials Needed

To make a wood marking gauge, there are a few materials that you will need. First, you will need a suitable type of wood for the gauge body such as maple, birch, or walnut. You will also need a hardened steel marking wheel, a steel rod, and a brass knurled knob.

Other materials you may need include wood glue, sandpaper, and a saw for cutting the wood to the appropriate size. Having a ruler or measuring tape on hand will also be helpful in ensuring precision when cutting and marking the wood. By having all the necessary materials, you can create a durable and high-quality wood marking gauge that will aid you in your woodworking projects.

With a little bit of practice, you’ll be able to make precise markings on your wood with ease.

Wooden Block

If you’re looking to create your own unique wooden toy, a wooden block is a great place to start! Making your own wooden block can be a fun and creative project that even kids can get involved in. To start, you’ll need a few key materials: a block of wood, sandpaper, a saw, and a drill. The type of wood you choose will depend on your personal preference, but some great options are birch, beech, and maple.

Once you have your block of wood, you’ll want to use a saw to cut it down to your desired size. Then, use sandpaper to smooth out any rough edges and drill holes if you want to add any extra details. With a little bit of creativity, you can make a wooden block that’s not only fun to play with, but also a beautiful accent piece for your home.

So why not give it a try and see what you can come up with?

Blade

Blade When it comes to making a blade, a few key materials are necessary for creating one that is both strong and durable. The most important material is the blade steel, which is the part of the blade that is responsible for its sharpness and strength. High carbon steel is an excellent choice for a blade because it can withstand repeated use without losing its sharpness.

Another important material is the handle, which can be made from a variety of materials such as wood, bone, or plastic. It is essential to choose a sturdy and comfortable material that will allow for a good grip and enable the user to control the blade effectively. Other materials that may be needed include pins, screws, and glue for securing the blade to the handle, as well as grinding and polishing materials for finishing the blade itself.

With the right materials and careful craftsmanship, a blade can be created that is not only functional but also beautiful and long-lasting.

Wingnuts and Screws

When it comes to putting things together, wingnuts and screws are two of the most commonly used materials. These fasteners can be found in almost every DIY project, from building a bookshelf to repairing a bike. But before you start your next project, it’s important to make sure you have all the materials needed to get the job done right.

For wingnuts, you’ll want to have a few different sizes on hand to accommodate different threading sizes. Screws also come in various lengths and widths, so it’s important to have an assortment to ensure you have the right size for your specific project. Plus, make sure you have the proper tool to tighten and loosen these fasteners, such as a wrench or screwdriver.

Keeping your hardware supplies organized can also save you time and frustration when starting your next project. Whether you’re a DIY enthusiast or a professional contractor, having a well-stocked toolbox that includes wingnuts and screws are essential for any project.

Step-by-Step Guide

Making your own wood marking gauge is an easy and satisfying project, and it can save you money compared to buying one. To start, you’ll need a piece of hardwood that’s about 12 inches long and 2 inches wide. Measure and mark the center of the board, then use a saw to create a notch that’s about 1 inch deep and 3/8 inch wide at the center mark.

Next, sand the edges and smooth out any rough spots. After that, create the fence by cutting a small piece of wood that’s about the same width as the notch and gluing it perpendicular to the board about an inch from the notch. Sand and smooth the fence as well.

Finally, add a bolt and wing nut at the top of the gauge to hold the marking tool in place. Your new wood marking gauge is now complete and ready to use on your next woodworking project!

Step 1: Cut the Block

Cutting the block is the first step towards creating a beautiful sculpture. When starting, it’s important to choose the right block size for your project. Once you have your block, it’s time to start cutting.

Begin by marking out the areas you want to cut, using a pencil or chalk. Take your time to ensure that you have the correct measurements and that your lines are straight. Once you have your marks, it’s time to start cutting the block.

Use a saw or chisel to make your cuts, but be sure to be careful as it can be dangerous work. Take it slow and steady, slowly chipping away at the block until you have the desired shape. With patience and practice, you’ll soon become an expert at cutting blocks for your sculptures, creating beautiful works of art that will be admired for years to come.

Step 2: Create Blade Slot

Now that you have gathered the necessary tools and materials, it’s time to move onto the next step of creating your blade slot. To begin, mark the center point on the weapon with a pencil or marker. Take the chisel and place it on the center point, then use a hammer to gently tap on the chisel until it slowly penetrates the metal.

Continue to work the chisel back and forth until you create a slot. Be careful not to force the chisel too hard, as this can cause the metal to crack or deform. As you work, test fit the blade periodically to ensure a snug fit.

Once the slot has been created, use the metal file to smooth out any rough patches or burrs. And just like that, you have successfully created a blade slot for your weapon! Remember to take your time and work carefully to ensure a clean and precise result.

Step 3: Attach Blade and Wingnuts

Once you’ve assembled your fan blades and motor, it’s time to attach the blade to the central hub. Start by positioning the fan blades onto the hub, ensuring that each blade is an equal distance from the one next to it. Then, slide the wingnuts through the holes on the hub and tighten them firmly by hand.

A secure and evenly screwed blade will help to ensure maximum efficiency and longevity for your fan. Don’t worry if your fan doesn’t immediately turn on – it’s normal for some new appliances to require a quick balance check before operation. Once you’ve completed this simple step, your fan should be good to go, providing you with a cool breeze for years to come.

Remember to conduct regular maintenance checks, such as cleaning the blades and motor, to keep your fan running smoothly.

Step 4: Cut Marking Line

After marking the cutting line on your fabric, it’s time to cut it using your scissors or rotary cutter. Make sure to follow the markings accurately to ensure that your fabric pieces are precise. Hold the scissors or rotary cutter firmly and begin cutting along the marked line.

Avoid cutting too close to the markings as it may alter the size and shape of your fabric pieces. If you’re using a rotary cutter, be careful not to cut yourself as the blade is very sharp. Once you’ve finished cutting, double-check your fabric pieces to ensure that they’re equal in size and shape as per your requirements.

Remember to store your scissors or rotary cutter safely after use to avoid any accidents or injuries. Cutting is a critical step in sewing, and precision is crucial to ensure that your project turns out how you envisioned it. So take your time, be patient, and enjoy the process.

Step 5: Adjust Blade and Get Accurate Markings

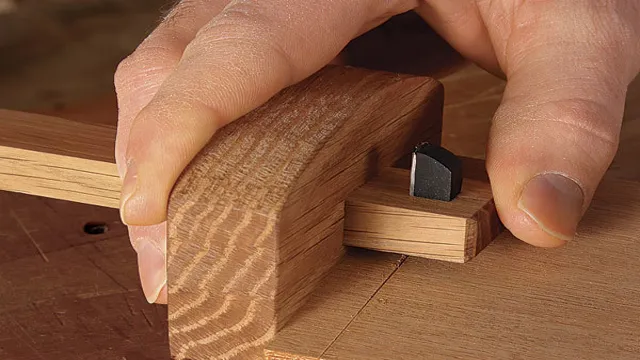

Adjust blade Now that your angle indicator is set up, it’s time to adjust the blade. Begin by loosening the knob that secures the blade in place, which will allow you to adjust the blade’s position. Align the blade with the angle indicator and tighten the knob to secure the blade back in place.

It’s essential to check your blade’s position, as a slight misalignment will make all measurements inaccurate. To ensure your markings are accurate, double-check the angle indicator’s alignment with the blade each time you reposition it. Once you’ve adjusted your blade, it’s time to test out your markings on your chosen material.

If they’re still off, readjust the blade until your markings are accurate. It may take a few tries to get it perfect, but once you have, you’ll be able to create accurate markings consistently. In conclusion, by adjusting the blade correctly, you’ll be well on your way to achieving accurate markings on your materials.

Remember, double-check your blade’s alignment with the angle indicator, and keep adjusting until your markings are perfect.

Tips and Tricks

If you’re looking for a simple and cost-effective way to make a wood marking gauge, you’re in the right place. The first step is to gather your materials: a straight piece of wood, a saw, a marking knife, a ruler, and a drill. The next step is to cut your wood to the desired length, typically around 6-8 inches.

Once you’ve done that, it’s time to create the cutting blade by sharpening the end of the wood with your marking knife. Use your ruler to mark where you want the cutting blade to start and stop. Then, use a drill bit to create a hole for the blade to slide in and out of.

Finally, insert the blade into the hole and secure it with a screw or bolt. Congratulations, you’ve just made a marking gauge! It’s a versatile tool that can be used for a range of projects, such as transferring measurements and marking out joints. Plus, it’s a great way to save money and add a personal touch to your woodworking projects.

Use Sharp Blade

Having a sharp blade is key to achieving that perfect cut, and it’s a game-changer when it comes to cooking. But did you know that using a dull blade can actually be dangerous? Not only is it more likely to slip, but it requires more force to make a cut, which can lead to accidents. So, always make sure your blade is sharp before using it.

But how do you keep your blade sharp? First, invest in a high-quality knife sharpener or take your knives to a professional to get them sharpened. And when using your knives, make sure to only use them on cutting boards that won’t dull the edge. Avoid using ceramic plates or glass cutting boards, as they can quickly dull the blade.

It’s also important to avoid using your knives to cut through bones, as this can damage the blade and dull it quickly. Remember, a sharp knife is not only safer, but it also makes cooking easier and more enjoyable. So, take the time to properly care for your knives and always use a sharp blade.

Your meals (and fingers) will thank you!

Screw Wingnuts Tightly

If you’ve ever struggled with loose wingnuts while working on a project, you know how frustrating it can be. Luckily, there’s an easy fix to this problem: screw them tightly! This may seem like a no-brainer, but it’s important to use enough force to ensure that the nuts will stay secure. One helpful tip is to use pliers or a wrench to give yourself a better grip and more leverage.

It’s also important to make sure that the wingnuts are threaded properly before tightening, to avoid any damage to the bolts or other components. By screwing the wingnuts tightly, you’ll be avoiding any potential mishaps down the road and ensuring a solid, durable finished product. So the next time you’re working on a project, remember to take a little extra time and effort to screw those wingnuts tightly, and you’ll be rewarded with a job well done.

Choose the Right Wood

Choosing the right wood for your project can make a huge difference in the finished product. One of the most important considerations is the type of wood itself. Hardwoods like oak, maple, and cherry are popular choices for their durability, while softer woods like pine and cedar are often used for their affordability.

Another factor to consider is the color and grain pattern of the wood – some species have distinct, eye-catching grains that add character and visual interest to the finished piece. It’s also important to consider the moisture content of the wood, as this can affect its stability and resistance to warping or cracking over time. Ultimately, the right choice of wood depends on your individual project and budget, so don’t be afraid to consult with a professional or do some research to find the best fit for your needs.

By taking the time to choose the right wood, you’ll ensure that your finished product is both beautiful and long-lasting.

Conclusion

So there you have it, folks – a simple and straightforward guide on how to make your own wood marking gauge. With just a few basic tools and materials, you can create a reliable and durable marking tool that’s perfect for all your woodworking needs. And not only that, but you’ll also have the satisfaction of knowing that you made it yourself – a true DIY project! So get out there, get crafting, and start marking up your wood with style and precision.

Your future woodworking projects will thank you!”

FAQs

What is a wood marking gauge?

A wood marking gauge is a tool used to mark lines parallel to the edge of wood.

What materials are needed to make a wood marking gauge?

Wood, a cutting tool, a measuring tool, a marking tool, and a tightening mechanism are the materials required to make a wood marking gauge.

How do you make a wood marking gauge?

To make a wood marking gauge, follow these steps:

1) Cut a rectangular piece of wood

2) Shape one end of the wood into a handle

3) Measure and mark the distance from the handle to where the marking tool will be placed

4) Cut a groove for the marking tool to fit into

5) Insert the marking tool and tighten it in place with the tightening mechanism

6) Sand and finish the wood for added durability.

What is the purpose of a wood marking gauge?

The primary objective of a wood marking gauge is to mark lines parallel to the edge of the wood.

Are there different types of wood marking gauges?

Yes, there are several types of wood marking gauges, including mortise gauges, cutting gauges, and scribing gauges.

How do you adjust a wood marking gauge?

To adjust a wood marking gauge, loosen the tightening screw and slide the marking tool to the desired location. Then tighten the screw to hold the tool in place.

Can a wood marking gauge be used on other materials besides wood?

Yes, a wood marking gauge could be used on any material that can be marked or scored with a marking tool.