How to Measure ft lbs without a Torque Wrench: Tips and Tricks for Accurate Results

If you’re a DIY enthusiast or a handyman, then you must know the importance of tightening fasteners to their recommended ft-lbs (foot-pounds) or torque. But what happens when you don’t have a torque wrench, or simply forgot it at home? Is it possible to measure ft-lbs without it? The answer is yes! In this blog post, we’ll provide you some alternative methods to measure ft-lbs without a torque wrench, which will come in handy when you least expect it. More importantly, we’ll discuss why measuring ft-lbs is essential and how it can affect the integrity of your fasteners.

So, let’s dive in and learn some quick and simple ways to measure ft-lbs, shall we?

Understanding ft-lbs

If you want to understand how to measure ft-lbs without a torque wrench, it’s essential first to comprehend what ft-lbs represent in the first place. Ft-lbs, or foot-pounds, are a form of measurement that helps to determine the amount of force needed to tighten or loosen a bolt or nut with a specific level of torque applied. Essentially, it’s a measurement of work done over a specified distance.

To measure ft-lbs without a torque wrench, you can use a simple handheld torque meter or even a torque conversion chart that matches the bolt size, grade, and thread pitch to determine the correct ft-lbs of torque required. However, it’s important to remember that these methods may not be as accurate as using an actual torque wrench and should only be used as a rough estimate. Ultimately, if you want to ensure precision in your torque measurements, investing in a high-quality torque wrench is the way to go.

Definition of ft-lbs

If you are working with tools or machinery, you are likely to come across the term ft-lbs. Ft-lbs stands for foot-pounds, and it is a term used in engineering to measure torque. In simple terms, torque is the force that is applied to an object so that it rotates around an axis.

Ft-lbs is a measure of the amount of torque applied to a specific point on an object, and it is calculated by multiplying the force and the distance from the axis. For example, if you apply a force of 10 pounds at a distance of 1 foot from the axis, the torque would be 10 ft-lbs. The concept of ft-lbs may seem unfamiliar at first, but it is essential to understand when working with tools and machinery, as it helps ensure that the right amount of torque is applied to achieve the desired results.

Why ft-lbs Matter for Bolt Tightness

As a DIY enthusiast or mechanic, understanding the importance of ft-lbs in bolt tightening is essential. The term ft-lbs refers to the amount of force required to tighten or loosen a bolt. It stands for foot-pounds, which is a unit of energy.

The ft-lbs value indicates the amount of torque needed to secure a bolt correctly. Tightening the bolt with too little torque can result in a loose connection, while over-tightening it can break the bolt or cause severe damage. It is crucial to use the manufacturer’s recommended ft-lbs value for each bolt as it depends on various factors such as bolt size, material, and application.

Investing in a torque wrench can help you accurately measure the required ft-lbs for each bolt. By understanding ft-lbs and its significance, you can ensure the proper installation of bolts and enhance their lifespan, preventing accidents or damage caused by improper torque.

Alternative Tools to Measure ft-lbs

If you’re wondering how to measure ft lbs without a torque wrench, then don’t worry. There are a few alternative tools that you can use to measure torque without a torque wrench. One of the most popular ways is to use a beam-style torque wrench.

This type of wrench uses a beam that flexes when you apply force to it, and there is a scale that tells you how much torque you are applying. Another option is to use a click-style torque wrench. This type of wrench is similar to a beam-style wrench, but it makes an audible clicking sound when you reach the desired torque level.

You can also use a digital torque adapter, which can work with any ratchet or breaker bar. It displays torque in real-time and can be calibrated to be very accurate. Keep in mind that while these alternative tools can work, they may not be as accurate as a torque wrench, so it’s important to use them with caution.

Socket and Breaker Bar Method

If you’re looking for an alternative method to measure ft-lbs and don’t have a torque wrench on hand, there are a couple of techniques you can try. One of which is using a socket and breaker bar to measure torque. The socket and breaker bar method is commonly used by mechanics to measure torque.

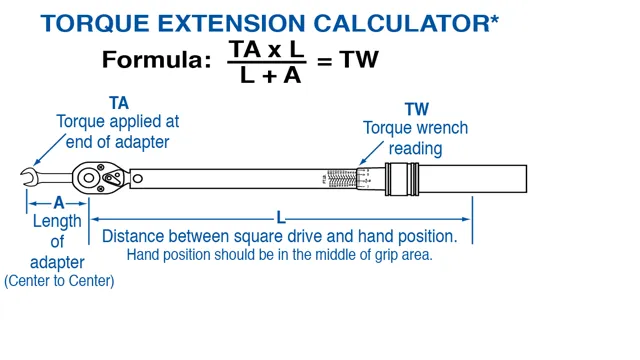

To use this method, you need to attach a socket to the end of a breaker bar and then tighten the fastener until it won’t turn anymore. Then, using a torque conversion calculator, you can determine the torque applied to the fastener. This method can be a bit imprecise, as you can’t be sure of the accuracy of the torque conversion calculator, and it requires a bit of guesswork on your part.

However, it’s a reliable alternative that can help you get the job done if you’re in a tight spot and don’t have immediate access to a torque wrench. So long as you know the specific torque requirements for the job, you can apply torque using this method and adjust accordingly.

Fish Scale Method

The fish scale method is a popular tool for measuring ft-lbs, but there are alternative options available. For instance, torque wrenches are highly precise and offer a greater level of accuracy than the fish scale method. Additionally, some mechanics prefer using electronic torque testers, which allow users to set the desired torque level and receive a reading instantly.

Another option is a beam-style torque wrench, which has a simple design but can still deliver accurate results. Ultimately, the tool you choose will depend on your specific needs and preferences. It’s important to consider factors such as cost, accuracy, and ease of use when selecting a torque measuring tool.

Deflection/Stretch Method

When it comes to measuring ft-lbs, the most common tool used is a torque wrench. However, not everyone has access to this tool or may prefer an alternative method. The deflection/stretch method is one such alternative that involves using a known length of material, such as a bolt or bar, and tightening it until it reaches a certain deflection or stretch.

By measuring the length before and after tightening, one can calculate the amount of force applied and therefore the corresponding ft-lbs. While this method may not be as precise as using a torque wrench, it can still provide a reasonably accurate measurement. It is important to note that the exact deflection/stretch needed will vary based on the material used and the specific application.

Nonetheless, this method can be a useful option for those who do not have access to a torque wrench or prefer a different approach.

Tips for Accurate Measurements

Measuring ft lbs without a torque wrench may seem like a daunting task, but it is possible with a few simple tricks. First, make sure you are using the correct tool to measure the torque, such as a torque adapter or torque stick. It’s important to apply the force at a right angle to the fastener, and to use a consistent speed and motion.

Additionally, pay attention to the click sound or vibration of the fastener, as this can indicate when you have reached the appropriate torque. Remember to make multiple measurements to ensure accuracy, and to record your readings for future reference. Although using a torque wrench is the most precise way to measure ft lbs, these tips can help you achieve accurate results without one.

Consistent Angle

When it comes to accurate measurements, maintaining a consistent angle is key. This means keeping the measuring tool perpendicular to the surface being measured, whether it’s a ruler, tape measure, or angle finder. It may seem like a small detail, but even a slight deviation from the proper angle can result in significant discrepancies in your measurements.

To ensure accuracy, take the time to position your measuring tool carefully and double-check that it remains in the correct position throughout the measurement. You can also use reference points or marks to guide you in maintaining a consistent angle. With some practice and attention to detail, you can improve the accuracy of your measurements and achieve more consistent results.

Consistent Force

Accurate Measurements When it comes to measuring accurately, one of the most important things to keep in mind is consistent force. Too much or too little force can result in inaccurate readings. To ensure consistent force, use a level surface and apply steady pressure.

Another tip is to double-check the calibration of your measuring tool before use. This can help you avoid errors caused by a misaligned or poorly calibrated tool. Additionally, make sure your measuring tool is appropriate for the object being measured.

Using a ruler to measure a curve, for example, may not provide the most accurate results. By keeping these tips in mind and taking the time to measure carefully, you can ensure accurate and reliable measurements every time.

Conclusion

In conclusion, while owning a torque wrench is the ideal way to measure foot-pounds, there are alternative methods that can be utilized in a pinch. Whether it’s using a bolt stretcher, a spring scale, or even a bit of math with a simple bathroom scale, there are creative ways to measure torque without breaking the bank. So, the next time you find yourself in a torque predicament, remember to think outside the box and get those foot-pounds measured with a little ingenuity.

“

FAQs

What is the formula for calculating foot-pounds (ft lbs) without a torque wrench?

To calculate ft lbs without a torque wrench, you need to multiply the force applied in pounds by the distance of the lever arm in feet.

Can you use a regular wrench to measure ft lbs?

Yes, you can. Attach the wrench onto the bolt and use a force gauge to measure the force applied. Then, multiply the force by the length of the wrench to get the ft lbs.

Can you estimate ft lbs by hand?

It is possible but not accurate. You can use a torque conversion chart to estimate ft lbs by tightening the bolt to a specific angle or using a specific bolt pattern.

How accurate is measuring ft lbs without a torque wrench?

It depends on the method used and the experience of the user. Using a force gauge and a wrench can give an accurate estimate, while estimating by hand can have a significant margin of error.

Is it necessary to measure ft lbs for every bolt?

It depends on the application and the manufacturer’s recommendations. Some bolts require specific ft lbs to ensure safety and functionality.

Can overtightening a bolt cause damage?

Yes, overtightening a bolt can cause the threads to strip or break, leading to a potential safety hazard.

Can undertightening a bolt cause damage?

Yes, undertightening a bolt may cause it to vibrate loose, leading to potential safety hazards, especially if the bolt is critical in the application.