How to Set a Torque Wrench in Nm for Accurate Tightening: A Step-by-Step Guide

If you are new to using a torque wrench or just need a refresher, you may be wondering how to set one in Nm. A torque wrench is a crucial tool for tightening bolts and nuts to a specific torque value to ensure proper fastening without damaging the surrounding parts. It is important to set the torque wrench correctly to achieve accurate results and prevent under or overtightening.

In this blog, we will go through step-by-step instructions on how to set a torque wrench in Nm, making your next DIY or mechanic job a breeze. So grab your torque wrench and let’s get started!

What is a Torque Wrench?

If you’re wondering how to set a torque wrench in nm, you’re not alone. A torque wrench is a tool used to tighten bolts and nuts to a specific torque value, which is measured in newton-meters (nm). To set a torque wrench, first determine the required torque value for the fastener you’re working on.

Then, adjust your torque wrench to that value by turning the handle or adjusting the digital display. Make sure to set the torque wrench when it’s not in use to avoid calibration issues. When using your torque wrench, keep it at a 90-degree angle to the fastener and apply pressure slowly and evenly until you hear a click or feel the handle release.

Remember that a properly set and used torque wrench is essential for ensuring the safety and reliability of your mechanical work.

Definition and Usage

A torque wrench is a specialized tool used to apply a precise amount of force, or torque, to a nut or bolt. This is particularly important in various mechanical applications where over-tightening or under-tightening can cause potential hazards. A torque wrench typically has a socket on one end and a handle on the other.

The handle is designed to be adjusted to a specific level of torque, which is displayed either on a dial or a digital readout. Once the torque wrench is set to the desired level, the operator can apply force to the wrench until the desired torque is reached. The wrench will then click or release once the designated amount of torque has been applied, indicating that the operator should stop tightening.

This tool plays an essential role in engineering, automotive, and other industries that require precise torque settings.

Types of Torque Wrenches

A torque wrench is a tool designed for tightening bolts or nuts to a specific level of tightness even when tightening by hand might not be enough. The wrench works by utilizing a calibrated mechanism that is used to indicate when the desired level of tightness has been reached. There are different types of torque wrenches that come in various sizes, shapes, and designs.

The most common forms of torque wrenches include the beam type, click type, and dial type torque wrenches. Each one of these wrenches functions differently, but the end goal is the same: to ensure that bolts and nuts are tightened to the appropriate torque value needed. For optimal results, it is essential to understand the differences between the different types of torque wrenches, and which one to use for a specific project.

Converting and Setting Torque Wrench in Nm

Setting a torque wrench in Nm is a straightforward process, but one that should be done correctly to ensure accurate tightening of bolts and nuts. First, you need to convert the torque values from other units to Nm. This can be done easily using conversion charts or online tools.

Once you have the Nm value, you can set your torque wrench accordingly. First, adjust the handle to the desired torque value using the scale on the wrench. Next, check the torque lock and adjust it accordingly to prevent the handle from moving during use.

Finally, test the torque wrench on a known torque bolt to verify that it’s calibrated correctly. Using a torque wrench set in Nm is essential for maintaining the integrity of mechanical systems and preventing costly repairs due to overtightening or undertightening of bolts and nuts. So, next time you use a torque wrench, don’t forget to set it in Nm and ensure a job done right!

Converting Torque Units: Nm to Ft-lbs

If you’re working with torque wrenches, you might have come across different units of torque measurement such as Nm and Ft-lbs. If you’re wondering how to convert Nm to Ft-lbs or vice versa, you’re not alone. Converting torque units might seem overwhelming, but it’s essential to ensure proper torque application and prevent under or over-tightening.

When working with Nm, you’re measuring the force applied to the fastener in Newton-meter units. On the other hand, Ft-lbs or foot-pounds, is the torque measurement unit that determines the amount of force applied to rotate an object one foot away from its center of rotation. As a result, when converting torque units from Nm to Ft-lbs, you need to multiply the Nm value by 0.

7376 to get the Ft-lbs equivalent. If you have a torque wrench and want to set it to a specific Nm value, you can typically find Nm-to-Ft-lbs conversion charts in the manual or online. It’s important to note that using the wrong unit of torque measurement can lead to inaccurate torque application and ultimately affect your work.

So, make sure you’re using the right torque unit, and if you’re unsure, seek advice from a professional.

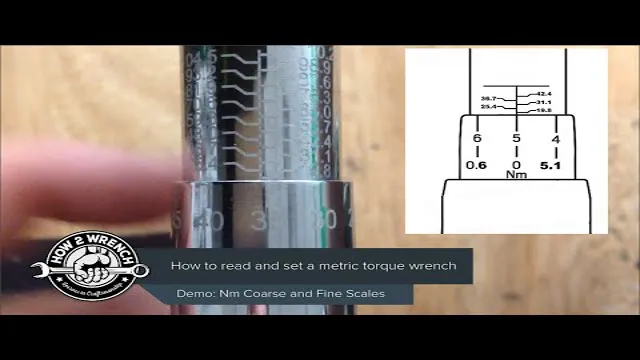

How to Set a Torque Wrench in Nm?

Setting a torque wrench in Nm may seem daunting at first, but it’s easier than you might think. First, you need to convert the torque value from the unit of measurement you have (e.g.

ft-lbs) to Nm. Luckily, this is a straightforward process with the help of online conversion tools or a conversion chart. Once you have the value in Nm, you can then set the torque wrench to the appropriate setting.

Depending on your wrench, this may involve adjusting a dial or twisting the handle until you reach the desired torque level. It’s important to follow the manufacturer’s instructions carefully to ensure you’re using the wrench correctly and not over or under-tightening your bolts. When setting the wrench, it’s also essential to ensure it’s properly calibrated and maintained for accurate readings.

By taking these steps, you can confidently use your torque wrench in Nm and ensure your fastenings are secure.

Important Tips for Using a Torque Wrench

If you’re working with a torque wrench, it’s essential to know how to convert and set it in Nm (Newton-meters). To do this, you need to understand the wrench’s units of measurement, as torque wrenches come in different types, sizes, and measurements. First, you need to convert ft/lbs to Nm by multiplying the value by

355 For example, if you have a 50-ft/lbs wrench, you’ll need to multiply it by 3558, which would give you 6

79 Nm. Once you’ve converted the value, you can set the torque wrench accordingly. Make sure to read the instructions and specifications carefully to avoid inaccuracies or damages to the tool and materials you’re working with.

Always double-check your measurements before starting any work to ensure precision and efficiency. With these tips, you can confidently use your torque wrench and achieve optimum results in your projects.

How to Check Torque Wrench Accuracy

If you want to ensure the accuracy of your torque wrench, there are a few steps you can take. First, make sure you have the right torque setting in newton meters (nm) for the job you are doing. Next, use a torque wrench calibration tool to check the accuracy of your wrench.

This tool measures the amount of torque your wrench is applying and compares it to a predetermined standard. If the results are different, adjust your wrench accordingly. If you don’t have a calibration tool, you can use a spring scale and a wrench adapter to get a rough idea of your wrench’s accuracy.

Simply attach the scale to the adapter, attach the adapter to your wrench, and pull until the wrench clicks. Then, compare the scale reading to the torque setting you have. If the reading is off, adjust your wrench accordingly.

By following these steps, you can ensure your torque wrench is accurate and avoid damaging your equipment or causing injury on the job.

Calibration Frequency

Calibrating a torque wrench is an essential part of achieving accurate and consistent results when tightening bolts and nuts. Over time, the mechanical components, such as the springs and internal components, can wear out or loosen, affecting the accuracy of the wrench’s reading. Thus it is necessary to check your torque wrench for calibration frequency.

You can test your torque wrench’s accuracy by using a calibration device known as a torque analyzer. The analyzer connects between the torque wrench and the fastener, and you tighten the fastener to a specific torque value to see if the wrench is providing the correct reading. If the analyzer detects an inaccuracy in the wrench’s reading, you may need to have it adjusted or repaired.

It’s recommended to check your torque wrench’s accuracy at least once a year or after significant usage. Frequent usage or wear and tear may reduce your wrench’s accuracy much faster, thus requiring more regular calibration. Regular calibration ensures that your torque wrench provides accurate torque readings, allowing you to work confidently and efficiently with the correct level of torque for each application.

Calibration Methods

If you’re working with torque wrenches regularly, it’s essential to ensure their accuracy for safe and precise torque settings. One way to do so is with calibration methods. Start by checking the manufacturer’s guidelines for how often to calibrate your particular torque wrench.

Then, you can use a torque calibration tester or a torque analyzer to test the accuracy of your wrench. Both methods involve applying a known amount of torque and checking it against your wrench’s reading. If the readings are within the manufacturer’s precision range, your wrench is good to go.

If not, you may need to have it recalibrated by a professional or consider replacing it altogether. Remember to have written records of your calibration tests for both accuracy and compliance reasons. By following calibration methods, you’ll ensure that you’re working with safe and precise torque wrenches.

Conclusion and Recap

In conclusion, setting a torque wrench in Nm is like finding the perfect balance of power and control. Just like adjusting the tension on a guitar string, you need to use just the right amount of force to achieve optimum performance. By carefully following the manufacturer’s instructions, you can ensure that your torque wrench is set to the exact specifications required for the job at hand.

So, let’s torque things up and get ready to achieve perfect precision! Remember, with great power comes great responsibility – so use your torque wrench wisely and always aim for the perfect balance of strength and accuracy.”

FAQs

What is a torque wrench and how does it work?

A torque wrench is a tool used to apply a specific amount of force (torque) to a bolt or nut. It works by applying a rotational force to the bolt, with a gauge or indicator letting the user know when the desired torque has been reached.

How do you convert foot-pounds (ft-lbs) to newton-meters (Nm) for torque settings?

To convert ft-lbs to Nm, multiply the ft-lbs measurement by 1.356. For example, 50 ft-lbs would be equivalent to 67.8 Nm.

How do you adjust a torque wrench to a specific measurement in Nm?

First, set the torque wrench to the lowest setting. Then, turn the wrench handle until the desired Nm measurement is shown on the gauge or indicator. Note: Always refer to the manufacturer’s instructions for specific guidance on adjusting your torque wrench.

Can you use a torque wrench for both tightening and loosening bolts?

Yes, torque wrenches can be used for both tightening and loosening bolts. When loosening, however, it’s important to be careful not to exceed the maximum torque for the wrench.

What’s the difference between a click-type torque wrench and a digital torque wrench?

A click-type torque wrench emits an audible “click” sound when the desired torque has been reached, while a digital torque wrench displays the torque measurement numerically on a screen. Both types of wrenches are accurate and effective, but some users may prefer one over the other for personal preference or specific applications.

How often should you calibrate your torque wrench?

It’s recommended to calibrate your torque wrench at least once a year or after 5,000 cycles of use (whichever comes first). If the wrench is dropped or otherwise damaged, it should be recalibrated immediately.

Can you use a torque wrench on all types of bolts and fasteners?

Torque wrenches can be used on most types of bolts and fasteners, but it’s important to make sure the wrench is compatible with the specific size and application. Always refer to the manufacturer’s instructions and follow best practices for safe, effective use of your torque wrench.