If you’re new to metalworking, you may have heard about DRO on a metal lathe and wondered what it means. Don’t worry; you’re not alone. DRO, or Digital Read Out, is an essential tool used in most modern metal lathes to improve accuracy and precision in machining processes.

Understanding how a DRO system works is vital to getting the most out of your lathe and producing high-quality parts. In this blog, we’ll take you through the basics of DRO on a metal lathe, its benefits, and how it works. By the end, you’ll have a clear understanding of why DRO is an invaluable tool for any metalworker.

So, let’s dive into the world of DRO and unlock the potential of your lathe.

What is DRO?

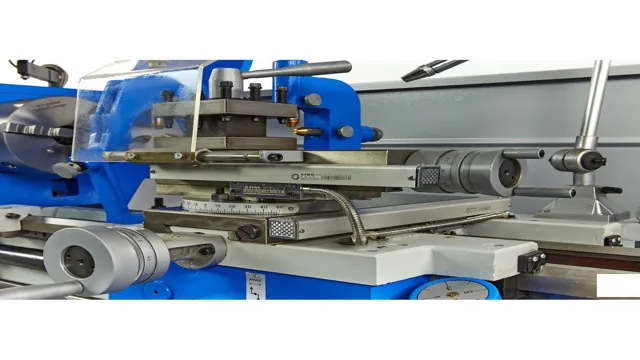

If you’re looking to learn more about metal lathes, you may have come across the term “DRO.” So, what is DRO on a metal lathe? DRO stands for Digital Readout, and it’s a device that helps you measure the movement of the cutting tool with high levels of accuracy. Essentially, a DRO is a digital display that shows you the position of the cutting tool in relation to the workpiece.

This technology can help you improve your precision and accuracy in machining, as well as increase your productivity and reduce scrap. With a DRO, you can easily make the necessary adjustments to your cuts, ensuring that your finished product meets your specific requirements. So, if you’re serious about metalworking, a DRO is a worthwhile investment to consider.

Definition and Function

DRO, or Dynamic Remarketing Optimization, is a form of digital advertising that involves using data to display personalized ads to potential customers based on their interests and browsing history. It works by tracking a user’s behavior on a website and then using that information to create targeted ads that are more likely to convert. These ads can appear on various platforms, including social media, search engines, and websites, and they are often more effective than generic ads since they are tailored to the user’s specific interests.

DRO is an essential tool for companies looking to increase their online sales and reach a wider audience. By leveraging user data, DRO helps businesses create more meaningful connections with their customers and ultimately drive more revenue.

Types of DROs for metal lathes

DRO, metal lathes If you’re working with a metal lathe, you might want to consider investing in a DRO, or Digital Read Out. A DRO is an electronic device that displays the position of the machine’s axes with high accuracy and precision. This is incredibly useful for machinists because it eliminates the need for manual measurement devices such as calipers or micrometers.

Not only does this save time, but it also greatly reduces the risk of errors in measurement. There are several types of DROs available for metal lathes, including single-axis, two-axis, and three-axis systems. Single-axis DROs measure one axis of movement, such as the X-axis, while two-axis systems measure two, such as the X and Y axis.

The most advanced type, the three-axis DRO, measures all three axes of movement, including the X, Y, and Z axis. Your choice will depend on the level of accuracy you need and the complexity of your machine. With a DRO, operating a metal lathe has never been easier or more precise.

Importance of DRO on a metal lathe

If you’re working with metal lathes, you’ve probably heard of DRO or Digital Read Out. DRO is an essential part of a metal lathe that allows for precision measurement and more accurate cuts. It works by measuring the position of the carriage, cross-slide, and compound rest in real-time.

This data is then displayed on a screen, giving the operator a clear reading of the exact axis they are working on. This makes it easier to achieve precise cuts, reduce tool wear, and minimize material waste. DRO also reduces the amount of time spent on manual measurement and recording, giving more time for actual machining.

With advancements in technology, DROs are becoming more affordable and accessible, making them an integral part of modern metalworking. So, if you’re serious about metal machining, investing in a lathe with DRO is a wise choice.

Accuracy and Precision

The accuracy and precision of a metal lathe are crucial, especially when you’re working on complex projects. That’s why a Digital Read Out (DRO) is so important. It provides you with accurate and precise measurements so you can be sure your cuts are exactly where they need to be.

Without a DRO, it can be challenging to get the measurements you need to create intricate parts without making errors. Think of a DRO like a GPS for your metal lathe. You wouldn’t want to take a road trip without knowing where you’re going, right? The same thing applies to your lathe work.

A DRO gives you a clear destination so you can get there with ease. Investing in a DRO will make a significant difference in your metalworking projects, giving you the accuracy and precision you need to achieve successful results every time.

Time-Saving Benefits

If you’re looking to save time and increase your productivity on a metal lathe, investing in a Digital Readout system is essential. With a DRO, you can quickly and accurately measure your workpiece’s dimensions without having to rely on manual measurements. This eliminates the time-consuming process of juggling multiple tools and trying to get precise measurements by hand.

Instead, simply enter the dimensions into the DRO, and the machine will do the rest. The importance of a DRO cannot be overstated, as it allows for a faster setup time, fewer errors, and ultimately, increased efficiency. So why not make your job easier and invest in a DRO for your metal lathe today? It’ll save you time and hassle in the long run, and enable you to focus on the other important tasks at hand.

Ease of Use and Increased Productivity

When it comes to metal lathe machines, the addition of a digital readout (DRO) can greatly improve the ease of use and overall productivity. A DRO displays measurements of the lathe tool position, helping users achieve greater accuracy and efficiency in their work. This is especially important in industries such as aerospace and medical equipment production, where precision is crucial.

With a DRO, operators can quickly and easily make adjustments to the tool position without the need for time-consuming manual measurements. This leads to reduced setup time, decreased scrap rates, and ultimately, increased output. In short, a DRO is a valuable investment for any metal lathe machine, improving both the ease of use and overall productivity of the machine and its operator.

How to Use DRO on a metal lathe

When it comes to using a metal lathe, a DRO or digital readout system can be an incredibly useful tool. But what is DRO exactly? Well, it’s a device that displays measurements taken from the lathe’s axis as you work. This means that instead of having to measure everything by hand with a set of calipers, you can get precise measurements with the push of a button.

To use a DRO on a metal lathe, you’ll need to install the device on your machine and make sure it’s calibrated correctly. Once you’ve done that, simply input your desired measurements and let the DRO do the rest. With a DRO, you’ll be able to work faster and with greater accuracy, making your metalworking projects easier and more efficient than ever before.

So if you want to take your metalworking to the next level, consider investing in a DRO for your lathe today.

Installation and Calibration Process

Are you looking for a way to improve your metal lathe efficiency? A digital readout (DRO) may be the answer! Installing a DRO on a metal lathe involves a few steps, but it’s a relatively simple process. First, you’ll need to mount the DRO display and magnetic scales on your lathe. Next, you’ll need to connect the scales to the stepper motor encoder using the supplied cables.

Once you’ve completed the installation, it’s time to calibrate your DRO. The calibration process involves setting the origin point, which is the reference point for all measurements. You’ll also need to check the accuracy of your DRO, which can be done using gauge blocks or a dial indicator.

With your DRO properly installed and calibrated, you’ll be able to accurately measure your workpiece’s position and dimensions. This will allow you to make precise cuts, saving time and reducing waste. Don’t let complicated measurements slow down your metal lathe work; try installing a DRO today!

Operating the DRO System

If you are looking to use a Digital Read Out (DRO) system on your metal lathe, first make sure you have installed it correctly and calibrated the scales. Once you have done this, using the DRO on your lathe is relatively easy. Simply turn on the DRO, select the appropriate readout for your lathe, and begin using the machine as you normally would.

As you move the carriage or cross slide, you will see the measurements displayed on the DRO screen. This makes it much easier and quicker to make precision cuts, as you can easily see the measurements and make small adjustments without having to constantly use a separate measuring device. The DRO system is incredibly useful and efficient in a metalworking environment, saving time and increasing accuracy in tasks that may have previously been difficult or time-consuming.

So don’t be afraid to give it a try!

Conclusion

So to sum it up, dro on a metal lathe is like having your trusty GPS system in your car – it guides you with precision and accuracy to your desired destination. But instead of roads and highways, the DRO system uses scales and readouts to help metalworkers achieve the perfect cuts and shapes in their metalworking projects. With a DRO, you’ll never have to worry about imprecise calculations or errors in measurement again – it’s the ultimate tool for a craft that demands nothing less than perfection.

“

FAQs

What does DRO stand for in relation to a metal lathe?

DRO stands for Digital Read Out, which displays the position of the lathe’s cutting tool on a digital screen.

How does DRO improve accuracy on a metal lathe?

DRO provides real-time position readings, allowing for more precise and consistent cuts to be made.

Is DRO a necessary feature for a metal lathe?

No, it is not necessary, but it can greatly improve accuracy and productivity.

Can DRO be installed on an older metal lathe model?

Yes, DRO can be installed on older models, but it may require some modifications or retrofitting.

How much does DRO typically cost for a metal lathe?

The cost of DRO varies depending on the brand, model, and features, but it can range from a few hundred to several thousand dollars.

What other features should I consider when purchasing a metal lathe with DRO?

Other important features to consider include the size and power of the lathe, material capacity, and overall durability and reliability of the machine.

Can DRO be used on other types of machines besides a metal lathe?

Yes, DRO can be used on other types of machine tools, such as milling machines and grinders, to improve accuracy and precision.