What is SPC Output on a Digital Caliper and How Does it Improve Accuracy?

If you are new to using a digital caliper with SPC output, you may feel confused by all the numbers that appear on the screen. Understanding the output is essential for accurate measurements, and fortunately, it is not as complicated as it may seem. In this blog post, we will break down the SPC output into digestible chunks, so you can make sense of what the digital caliper is telling you.

Think of it like learning a new language – once you understand the basic vocabulary, you can start to read and interpret the data with ease. So grab your digital caliper and let’s dive in!

What is a Digital Caliper

If you’ve ever used a digital caliper, you might have noticed the term “SPC output” on the device. SPC stands for Statistical Process Control, which is something that can come in handy if you’re looking to accurately measure and control a manufacturing process. Essentially, the SPC output on a digital caliper allows you to transfer data from the caliper to a computer or other device, where it can be analyzed and used to keep track of process control.

This can be useful if you need to make sure that your machine is operating within certain specifications or if you need to quickly analyze the data collected by the caliper. With SPC output, you can streamline your measurement processes to make things more efficient and accurate, which can be a huge benefit in certain industries.

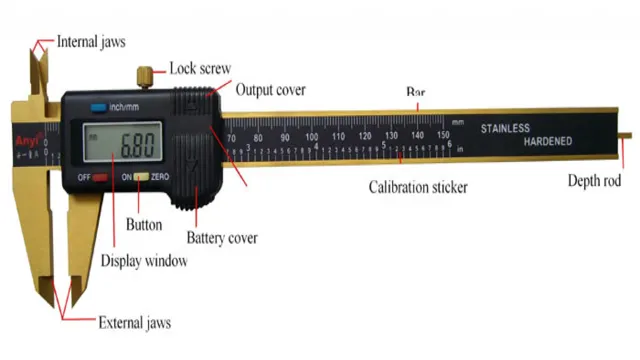

Definition and Components

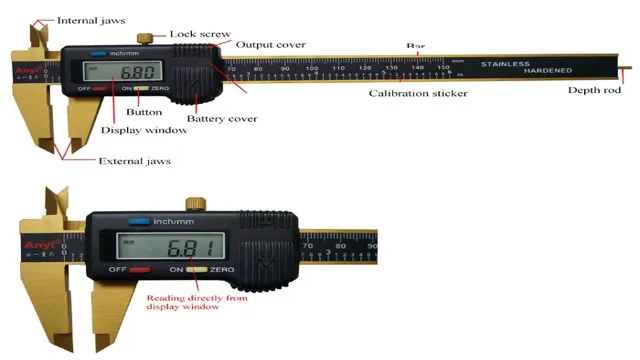

A digital caliper is a precision measuring instrument used to measure distances with high accuracy in various applications. It has two jaws that can be adjusted by using a thumb wheel or a button, and can measure in both metric and imperial units. Components of a digital caliper include the main body, measuring jaws, depth probe, LCD display, and the battery compartment.

The measuring jaws, which can be external or internal, are used to determine the distance between two points, while the depth probe is designed to measure the depth of holes or cavities. The LCD display shows the measurement in either inches or millimeters and provides accurate readings up to thousandths of an inch or hundredths of a millimeter. Digital calipers are commonly used in industries such as manufacturing, engineering, and metalworking for measuring the thickness of materials, the depth of drill holes, or the diameter of cylindrical objects.

With its high precision and ease of use, the digital caliper is a dependable tool for both professionals and DIY enthusiasts alike.

SPC Output on a Digital Caliper

SPC output on a digital caliper refers to the statistical process control output feature that allows users to collect data and analyze it for quality control. Simply put, this feature makes it possible to track the measurements taken by the digital caliper over time, giving manufacturers the ability to identify defects or inconsistencies in their production process. SPC output data can be transmitted to a computer or other device for analysis and graphing.

This information helps manufacturers prevent defects by identifying potential problems before they occur. With the SPC output on a digital caliper, manufacturers can make informed decisions about their production process and ensure consistent quality. Overall, the SPC output feature is an important tool for quality control in manufacturing and is a must-have for businesses that are interested in maintaining consistent production standards.

Definition and Application

SPC Output on a Digital Caliper Simply put, SPC output on a digital caliper means the ability of a digital caliper to transmit data to a Statistical Process Control (SPC) software for further analysis. A digital caliper is an instrument used in measuring thickness, length, diameter, and depth of an object with high precision. SPC software on the other hand analyses data to determine if a process is under statistical control or not.

This enables businesses to make informed decisions and improve the quality of their products. With SPC output on a digital caliper, measurements are taken and transmitted to the SPC software in real-time. This ensures that data analysis is accurate, efficient and consistent.

Additionally, it eliminates the possibility of human error in data entry. SPC output on a digital caliper is especially useful in industries where precision and accuracy are critical, such as manufacturing, engineering, and quality control. Overall, it is evident that SPC output on a digital caliper is vital in ensuring optimal data collection, analysis and ultimately improving product quality.

Benefits and Limitations

SPC Output on Digital Caliper A digital caliper is a handy tool that provides valuable measurements for various applications. With technological advancements, digital calipers now come equipped with statistical process control (SPC) output features. The SPC output on digital calipers provides several benefits, including accurate and precise measurements, time-saving, and improved data management.

However, the SPC output feature may come with some limitations that can impact its effectiveness. For instance, the feature requires a high level of expertise and knowledge to operate, which may pose a challenge for beginners. In addition, the SPC output feature may be limited to specific software or may not work with other measurement instruments.

Despite its limitations, the SPC output on digital calipers remains an essential feature for quality control and process improvement in manufacturing, engineering, and scientific fields. With training and proper use, users can take advantage of its benefits and unlock the full potential of their digital calipers.

How to Use SPC Output on a Digital Caliper

SPC output on a digital caliper is a feature that allows you to transfer measurements to a computer or other application for analysis and further processing. It simplifies the process of taking measurements and reduces the chance of human error. The SPC output transfers information in a digital format, allowing you to store your data automatically.

When using SPC output on a digital caliper, it’s important to ensure you have the correct software installed on your computer, as different devices use different software. You can also use the feature to transfer data to spreadsheets, databases, and other applications, providing plenty of versatility and flexibility. Overall, the SPC output is a useful feature that can save time and reduce errors, making it an important consideration when shopping for a digital caliper.

Step-by-Step Guide

If you’re looking for precise measurements in your workshop or lab, then a digital caliper with SPC output is a highly recommended tool. The SPC or Statistical Process Control output on a digital caliper measures the quality and consistency of a product or process and provides details about the measurement’s variability and deviation from a set standard. Using this feature when taking measurements can help you monitor the accuracy of your equipment, detect any changes in the process, and ensure your products meet the necessary quality standards.

To use the SPC output on your digital caliper, you need to connect it to a computer or data collector via a cable or wireless connection. Once connected, you can record and analyze the measurement data and optimize your production process accordingly. With a properly calibrated and used digital caliper, you can achieve the highest accuracy in your work.

Conclusion

In conclusion, SPC output on a digital caliper stands for Statistical Process Control, which is essentially a fancy way of saying that your caliper is smart enough to give you precise measurements and data that you can use to improve your manufacturing processes. So the next time you see those three letters on your digital caliper, remember that you’re not just measuring a piece of metal – you’re empowering yourself with invaluable insights into the world of manufacturing. Now that’s something to calibrate your mind around!”

FAQs

What does SPC output mean on a digital caliper?

SPC output on a digital caliper refers to the ability of the caliper to transmit measurement data to a computer or external device for analysis and monitoring.

How can I use the SPC output on my digital caliper?

The SPC output on a digital caliper is typically used for statistical process control (SPC) applications, where data can be analyzed to identify trends, improve quality control, and increase efficiency.

Is SPC output a standard feature on all digital calipers?

No, not all digital calipers have SPC output capabilities. It is important to check the specifications of the caliper you are interested in purchasing to ensure it has the SPC function.

What type of software is compatible with SPC output on a digital caliper?

There are many software programs available that accept SPC output from digital measuring instruments, such as Excel, Minitab, and QC-CALC.

Can SPC output be used for real-time process monitoring?

Yes, SPC output can be used for real-time monitoring of production processes, allowing for quick adjustments and improvements as needed.

Are there any special cables or equipment needed to use SPC output on a digital caliper?

Depending on the caliper and software being used, there may be special cables or equipment needed to properly transmit and analyze the SPC data.

Can SPC output on a digital caliper improve overall quality assurance and control?

Yes, utilizing SPC output on a digital caliper can lead to improved quality assurance and control by identifying areas for improvement and ensuring consistency and accuracy in measurements.